Improve Assembly, Packaging & Decorating of Consumer Goods

Plasma & Flame Surface Treating Prepare Surfaces for Optimal Bonding

The vast majority of plastics, composites and metals used to produce consumer goods are non-porous and have very low surface energy. This makes them difficult to bond with inks, adhesives, paints and coatings used to decorate and assemble the products.

From printing golf balls to assembling furniture, Enercon plasma & flame treaters are used by consumer goods manufacturers to clean, etch and functionalize surfaces immediately prior to applications that requiring bonding. This increases the surface energy and wettability of the surface which promotes adhesion.

Packaging applications include ensuring label adhesion on containers, date & lot coding on caps & containers, direct printing, folding carton assembly, as well as supporting specialized coating & metallization on cosmetic packages and optical lenses.

Decorating applications that may also benefit from surface treatment include painting, and coating. Adhesive assembly applications include structural bonding of dissimilar materials, as well as the installation of gaskets, profiles and adhesives tapes.

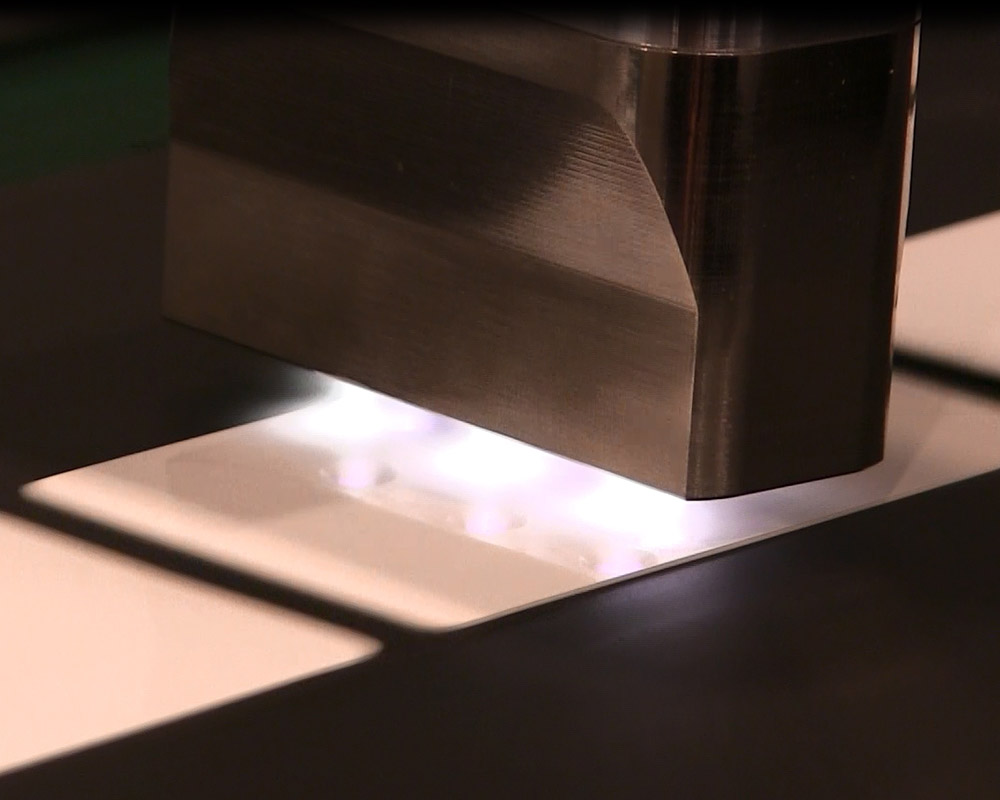

The image below demonstrates the impact of surface treatment as the liquid wets out on the treated surface versus beading up on an untreated low surface energy surface.

FROM OUR LIBRARY Consumer Goods Applications

COMMON CONSUMER GOODS APPLICATIONS Products & Materials Treated

-

Appliances

-

Furniture

-

Lenses

-

Lighting

-

Packaging

-

Sporting Goods

-

Toys

-

Windows & Doors

-

Composites

-

Glass

-

MDF

-

Metals

-

PE

-

PP

-

PVC

-

Wood