Atmospheric Surface Modification Of Polymers For Biomedical Device Adhesion

Abstract Biomedical applications require polymers that react properly with the biological environment in which they are employed. Since biocompatibility involves the interface between the device and the biological environment, surface modification techniques can be critical to solve adhesion issues, avoiding costly changes of materials. Atmospheric surface modification techniques such as air plasma, flame plasma and…

Read MoreHow and why plasma and flame surface treating improve surface adhesion.

Common adhesion impediments found on surfaces. Non-porous and hydrophobic surfaces have low surface energy with few available bonding sites due to low levels of charged ions on the surface. Additionally, any type of surface contamination affects adhesion negatively. This contamination can include material additives & release agents which can migrate to the surface. Clean, Etch…

Read MoreAtmospheric Plasma and Flame Surface Treatment for Medical Applications

Get insight on how medical device manufacturers are using atmospheric plasma to eliminate adhesion challenges. What’s in the eBook? Learn how atmospheric plasma is helping users improve product quality, and increase production speeds. See what Enercon customers are saying “For medical printing applications, it’s imperative to follow the defined protocols. Enercon’s experience with medical device…

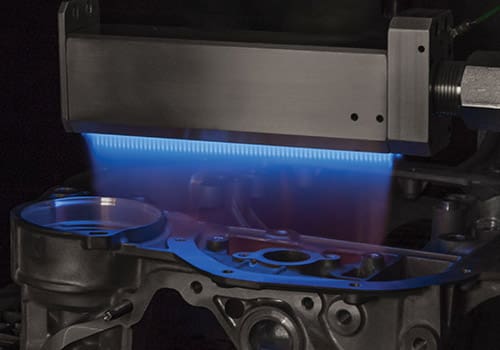

Read MorePlasma & Flame Treatment Prepares Aluminum Surfaces for Bonding

Bonding to aluminum can be major challenge. Engineers typically rely on adhesives to bond aluminum without welding. Depending upon application requirements, there are several adhesives and VHB foam tapes that have proven effective. However, all adhesive-based remedies are subject to failure if surface preparation is overlooked. Aluminum Surface Contaminates Aluminum is often annealed to achieve…

Read MoreContinuous Inkjet Printing for Industrial Manufacturing Applications

As a non-contact printing process, inkjet offers manufacturers tremendous production advantages including variable data, fast changeover and reliability at top line speeds. Applications abound for plastics and rubber in the wire & cable, packaging, coding & industrial manufacturing industries. However material properties, surface contamination, ink/material compatibility and durability requirements create challenges. Keys for successful ink…

Read MoreWhat Plasma Actually Does to a Surface to Improve Adhesion

Air plasma surface treating is an emerging green technology for leading manufacturers tasked with assembling and decorating plastics, composites, glass and metals. It is a powerful, yet relatively inexpensive technology that is used by both Fortune 100 companies and small operations to improve bond strength, product quality and throughput. You can see the effects of…

Read MoreTop 3 Strategies to Improve Your Adhesive Bonding Operations

Production & design engineers are challenged with developing manufacturing processes that yield optimal results for quality and throughput. Since many do not fully understand the chemistry aspects of interfacial surface adhesion, they rely on conventional production methodologies, which ultimately undermines the repeatability of their success. In this new webinar, industry experts Wilson Lee (Enercon Industries)…

Read MoreImprove Adhesion in Window & Door Manufacturing Processes

Learn how plasma & flame surface treatment are used to efficiently create strong bonds for the assembly, painting and decorating of windows and doors. Discover how these technologies work, see examples of specific industry applications, and get insights from the application experts at Enercon. Plus, gain access to info on our new plasma treating nozzles which are…

Read MoreWhy Manufacturers Use New Flame Technology to Improve Adhesion

Advances in flame surface treatment technology are fueling a renewed interest in flame as an automated method of improving surface adhesion. Today’s flame treaters are remarkably safe, reliable & effective at treating a wide variety of plastic, composite, metal and paperboard surfaces. Discover why flame is an ideal solution for high line speeds, complex surface…

Read MoreApplication Engineer’s Guide for using Plasma Treatment to Improve Adhesion

Plasma Surface Treatment is being used in dozens of industries for hundreds of applications. This 30-minute webinar provides insights into how engineers are using atmospheric plasma surface treating systems to improve surface bonding of inks, adhesives and coatings. This webinar includes: Access to the webinar includes both the recorded presentation and the presentation slides.

Read More