Advances In Adhesion With Co2-Based Atmospheric Plasma Surface Modification

Abstract The use of gas and/or liquid-phase carbon dioxide (CO2) with atmospheric plasma discharge surface pretreatment technology can remove micron and submicron particulates and hydrocarbon-based contaminations on plastics and metals. The cleaning process is based upon the expansion of either liquid or gaseous carbon dioxide through an orifice. The paper provides an understanding of the…

Read MorePlasma & Flame Surface Treatment Distance & Dwell Time Recommendations for Consistent Treatment Results

What is the ideal distance between the treatment head and the surface to be treated? The answer depends on the surface treater you are using and your specific application. However, there are some general guidelines that you should be aware of: Treatment Distance Treatment Dwell Time Treatment Angle Measuring Treatment Success Pretesting and good documentation…

Read MoreClean is good, but is it good enough for successful adhesion?

Smart manufacturers recognize the importance of a clean surface when bonding components. If a part is not clean, the adhesive will bond to the surface contamination rather than directly to the surface itself. Manufacturers commonly use a solvent to clean the surface. However, this isn’t always enough to produce the desired adhesive outcome. A clean…

Read MoreUV Flexo Ink Composition And Surface Treatment Effects On Adhesion To Flexible Packaging

Read the abstract below and download your copy of this informative technical paper which was presented at the TAPPI PLACE 2010 conference “UV Flexo Ink Composition and Surface Treatment effects on adhesion to Flexible Packaging”. Abstract UV flexo inks are becoming increasingly popular in flexible packaging and shrink sleeve applications, traditional markets for flexographic inks.…

Read MoreRoll Aluminum Surface Preparation for Packaging Applications

The packaging industries within North America and Western Europe consume the majority of the aluminum sheet and foil for making beverage cans, flexible packaging and foil wraps. The choice of alloy for these applications typically predetermines properties such as strength, formability and resistance to corrosion. Other requirements such as the surface finish, flatness and gauge…

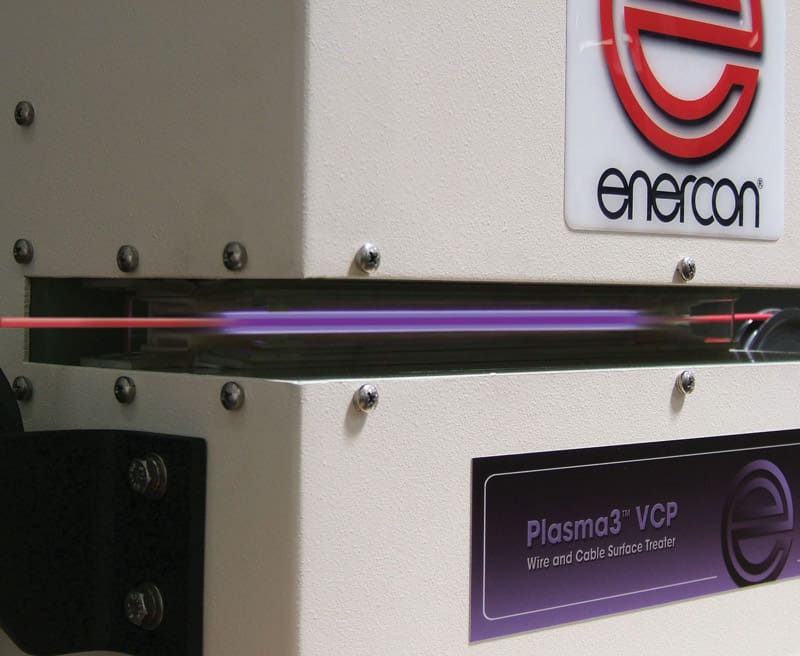

Read MoreDesmear & Descum Circuit Boards with Plasma Treatment

Complex printed circuit board constructions with ever-increasing layers and circuit densities benefit from Plasma3™ plasma treatment for descum, desmear, removal of carbon-based organics, PTFE activation, and surface preparation. Plasma processing of various board types historically have used vacuum plasma technologies. However, there is a need for increased processing capacities as the printed circuit board construction continue to…

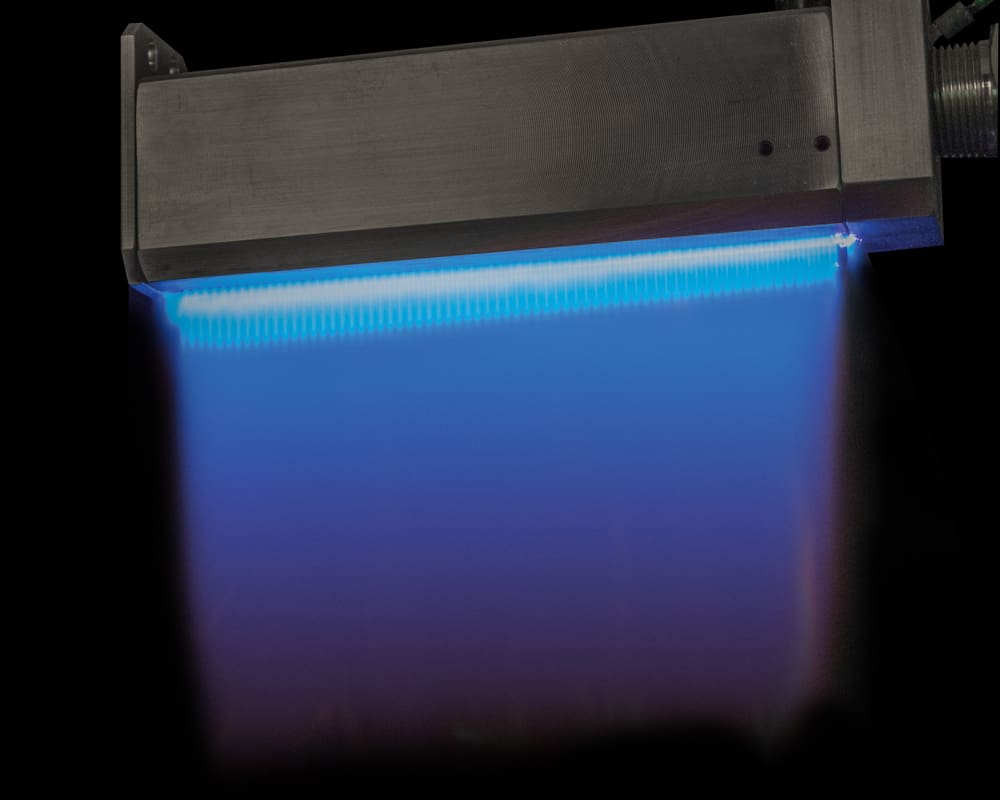

Read MoreHow and why plasma and flame surface treating improve surface adhesion.

Common adhesion impediments found on surfaces. Non-porous and hydrophobic surfaces have low surface energy with few available bonding sites due to low levels of charged ions on the surface. Additionally, any type of surface contamination affects adhesion negatively. This contamination can include material additives & release agents which can migrate to the surface. Clean, Etch…

Read MoreGetting Started with Flame Plasma

What’s in the eBook? Learn how flame plasma is helping users improve product quality, and increase production speeds. See what Enercon customers are saying “We’ve integrated Enercon flame treaters and we really enjoy working with Enercon because of their depth of knowledge in surface treating.”Jerry Schmit, Sr Applications Engineer, Midwest Engineering Solutions

Read MoreImproving UV Coating Results with Corona & Plasma Surface Preparation

UV coatings are a great choice for high value applications where scratch resistance and surface performance are essential. While traditional UV lamps are still used, the advancement of LED curing technology has improved operational efficiencies for numerous applications. This article reviews the importance of properly preparing surfaces for bonding with a variety of in-line surface…

Read MoreBonding Styrenic Copolymers to Replace PVC

The desire to find a cost-effective, yet environmentally friendly alternative to PVC is the focus of a new technical paper: Bonding Styrenic Copolymers and Thermoplastic Elastomers in the Quest to Replace PVC. The paper details current research on the benefits of using light-curable adhesives and surface treatment technology to optimize bond strength of competitive high…

Read More