Infographic: How to Enable Inkjet Printing on Wire & Cable

Digital inkjet printing on wire & cable provides manufacturers with productivity advantages including higher line speeds, faster changeovers, variable printing and reduced cost. This new infographic from Enercon shows how plasma surface treatment enables inkjet printing on wire & cable. It will also guide you through traditional marking methods and how to implement surface treatment…

Read MoreDyne Level Does Not Guarantee Surface Adhesion

Dyne levels are a great indicator of your chance for adhesion success. But dyne level does not guarantee adhesion. Let’s look at a few factors that affect adhesion results. These include coating and material compatibility, surface energy, process variables, material variables and ultimately bonding requirements such as entanglement. Coating (ink, adhesive, paint, etc…) and material…

Read MoreFlame Treatment Automotive Dashboard to Improve Paint Adhesion Video

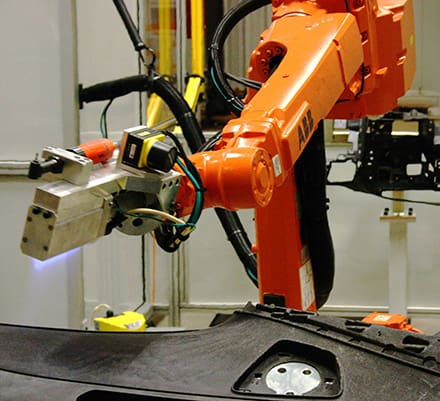

Enercon’s Flame Series surface treater treats an EVA automotive dashboard prior to painting. Treatment raise surface energy to promote paint adhesion. The flame treater is integrated with a robot that executes a treatment pattern based on a program actuated by a bar code scan on the part.

Read MoreFlame Treatment of Automotive Dashboard Improves Foam Adhesion Video

Enercon partnered with Midwest Engineering to develop a production ready flame treatment system for an automotive dashboard supplier. The goal of the system is to increase the receptiveness of the EVA dashboard surface to an adhesive which will hold foam padding in place. Enercon’s flame treater is integrated with a robot for precise treatment patterns…

Read MoreWhat Plasma Treating Does to a Surface Video Animation

Plasma Treatment cleaning, etching and functionalizing Atmospheric plasma treatment is used by manufacturers, converters and packagers to improve surface energy and adhesion. The animations below show how the process effectively functionalizes surfaces. These treatment systems diffuse reactive gases toward the surface under the influence of electrical fields. Low molecular weight materials such as water, absorbed…

Read MoreHow Plasma & Flame Surface Treating Works – Explainer Video

Sam is a Quality Engineer at Stick-It Inc. and he is having trouble with the adhesive bonding and printing of his manufactured parts. The adhesives won’t stick and the ink rubs off! He needs to find a solution quick and decides to call Enercon for help. Follow Sam through his journey of discovering how plasma…

Read MoreClean & Remove Surface Contaminates with Atmospheric Plasma (Video Demonstration)

Atmospheric plasma surface treaters promote adhesion by removing organic and inorganic surface contaminants. This example demonstrates atmospheric plasma’s ability to micro-etch or clean without damaging the integrity of the surface. Enercon’s Blown-ion plasma treater treats both conductive and non-conductive surfaces. It can be mounted over the production line or integrated with a robot for more complex…

Read MorePlasma and Flame Laboratory Surface Analysis

The best way to test the success of surface treatment is to immediately perform the next step in your process after treatment. If field evaluation is not possible, surface treating laboratory trials may be conducted with Enercon’s application engineers. They will test experiments with various plasma and flame treating technologies to determine which may be best for…

Read MorePlasma Treating Tubes Ensures Ink Adhesion and Increases Production Efficiency

Plastube is a Canadian manufacturer of innovative plastic tubes for the beauty, healthcare, food and pharmaceutical industries. The company produces and prints polyethylene tubes, tubes with an inner foil and exterior plastic and laminate tubes. Their mission is to make their customers’ brands shine. Package appearance for tubes sold in the retail marketplace is vitally…

Read MoreBeyond Dyne Levels: New Surface Analyzer Provides Insights in Enercon’s Laboratory

Enercon’s laboratory now includes a a KRUSS Mobile Surface Analyzer (MSA) to measure the effects of surface treatment. The MSA measures surface free energy with two liquid. Two parallel drops receive direct analysis of the contact angles and the derived results of the surface free energy. All steps are automated. The results enable well-founded statements…

Read More