Corona vs. Plasma

Enercon receives many questions about the differences and similarities between corona and plasma surface treating. In all cases, the context of the question is very important as some industries have adopted unique definitions of each term. Technically, plasma is the fourth state of matter produced by the ionization of a gas. And since corona ionizes atmospheric air (which is a gas), corona is actually a form of plasma.

{Related: What Plasma Treatment Actually Does to a Surface}

As stated, corona treaters ionize air. In the film, roll to roll, converting and extrusion industries the term corona treater is reserved for those systems which ionize air without any additional gases being employed. Depending on the dielectrics (electrodes and ground rolls) being used, the purple corona discharge may appear to be very smooth and consistent, or may include visual filamentary discharges which appear as “spikes.” Corona treating is a mature product in these industries and is an excellent and extremely efficient way to increase surface energy and adhesion for printing, coating and laminating film.

How different industries identify treatment technologies

In the film converting and extruding industries, the term plasma is reserved for those surface treaters which are supplied with additional gases to ionize such as argon, nitrogen or helium. Plasma systems are used when corona treatment, which again ionizes only air, are unable to produce the desired treatment results. In some cases, plasma treatment produces higher and longer lasting surface effects than corona, but the benefits must offset the additional equipment investment and operational costs.

As we look at industries outside of film and converting, corona and plasma are identified somewhat differently. Early corona systems that were used to treat objects tended to offer very low power and were only effective in limited applications. As the technology of these corona systems for treating objects evolved, they became significantly better at treating. Significant improvements in power supplies and the treatment discharge heads led to improved performance. However, manufacturers needed to overcome the market’s previous experience with the low performance of early corona treaters when treating objects. The term “Air Plasma” was coined to define these systems.

Air Plasma Technologies

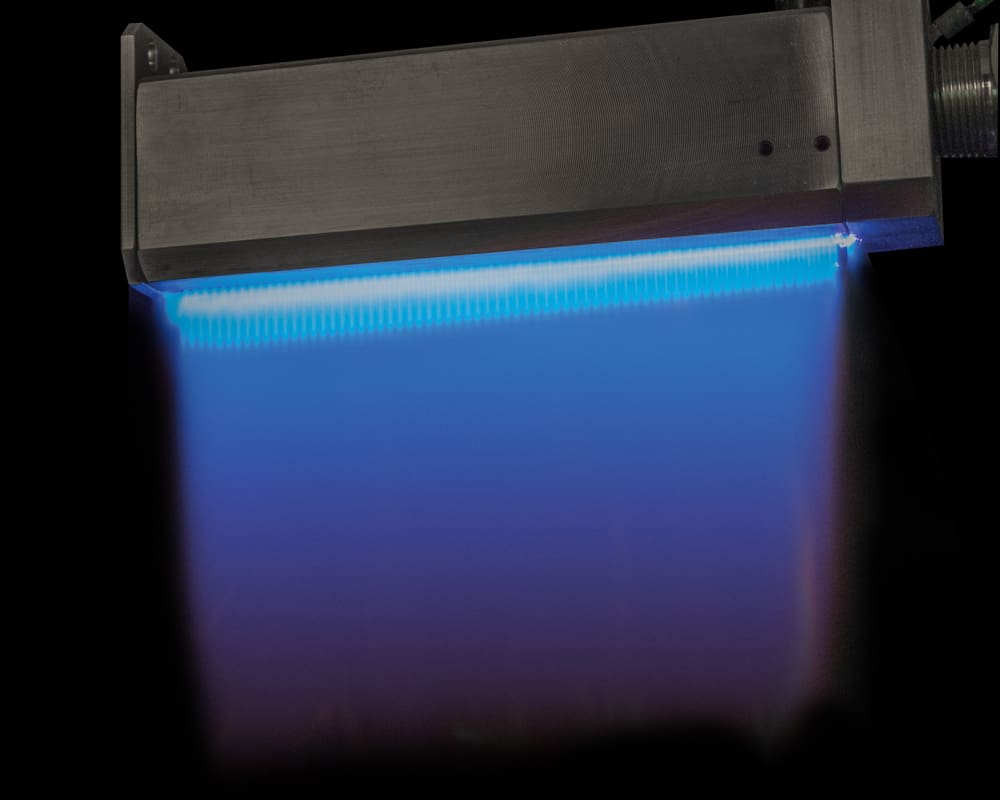

Within the Air Plasma family are two primary categories, Blown-arc Technology (see animated video) and Blown Ion Technology (see animated video). Blown Arc Systems are most similar to corona treaters. Blown Arc Air Plasma is formed by blowing atmospheric air past two high voltage power electrodes. The electrical discharge positively charges the ion particles surrounding it. Through direct contact, these particles positively charge the treated area of the object’s surface. This makes the surface more receptive to any applied substance such as inks. The discharge looks similar to the discharge you might see on a standard corona treater used in the film converting industry.

{Free eBook: Getting Started with Atmospheric Plasma}

Blown Ion Air Plasma Systems push pressurized air past a single electrode which discharges inside the treater head. The electrode creates positively charged ions in the surrounding air particles. The air pressure forces the air particles to accelerate off the tip of the head as a high velocity stream of charged ions are directed toward the substrate surface. Through direct contact, these particles positively charge the object’s surface increasing its surface energy and making it more receptive to inks and coatings. Generally speaking, Blown Ion Air Plasma Systems offer greater treatment results than Blown Arc Air Plasma.

A third category of plasma treaters are called Variable Chemistry Plasma Treaters. This technology ionizes gas chemistries instead of only atmospheric air. These systems can be effective at treating surfaces which are unresponsive to air plasma treatment.

The important thing to remember is not to let semantics get in the way of finding the surface treating solution that is best for your application. Enercon offers free laboratory testing with a wide variety of air plasmas, variable chemistry plasma, flame and corona technologies. Our application experts can help you determine which technology will provide the most economic and efficient adhesion promoting solution to meet your requirements. For more information, please contact us.