New Blown-ion™ 500 Plasma Surface Treating Technology Enables Rockwell Automation’s Switch from Print-and-Apply Labels to In-Line Digital Printing

When Rockwell Automation moved its contactor and relay production back to Milwaukee, Wisconsin, it had to develop an entirely new process for the changing volumes and available space. The new highly automated assembly line would also be a showcase of Rockwell’s automation capabilities, featuring Rockwell drives, motors, Independent Cart Technology (ICT), PLC’s, HMI’s, sensors, and…

Read MoreHow and why plasma and flame surface treating improve surface adhesion.

Common adhesion impediments found on surfaces. Non-porous and hydrophobic surfaces have low surface energy with few available bonding sites due to low levels of charged ions on the surface. Additionally, any type of surface contamination affects adhesion negatively. This contamination can include material additives & release agents which can migrate to the surface. Clean, Etch…

Read MoreGetting Started with Flame Plasma

What’s in the eBook? Learn how flame plasma is helping users improve product quality, and increase production speeds. See what Enercon customers are saying “We’ve integrated Enercon flame treaters and we really enjoy working with Enercon because of their depth of knowledge in surface treating.”Jerry Schmit, Sr Applications Engineer, Midwest Engineering Solutions

Read MoreAn Overview of Surface Treatment for Three-Dimensional Objects

If you’ve attempted to print, label, or otherwise decorate a three-dimensional (3-D) product, you’ve probably been frustrated by an ink or adhesive that refused to adhere to the part’s surface. You may have tried different types of ink or adhesive formulations to get the job done, perhaps even used chemical primers or batch-treating processes. Still,…

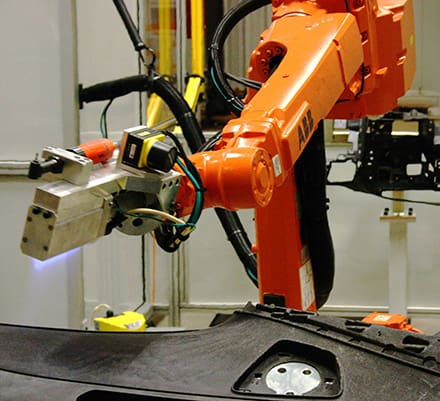

Read MoreAutomation Improves Plasma & Flame Surface Treatment Productivity

The manufacturing of virtually everything from toothbrushes to auto parts can benefit from the use of atmospheric plasma treatment and flame treatment during assembly and decorating operations. These technologies increase material surface energy to promote bonding with inks, adhesives, paints and other coatings. Companies in the medical, automotive, packaging, consumer products, wire & cable, sporting goods, furniture, and others markets find that…

Read MoreWhat Plasma Actually Does to a Surface to Improve Adhesion

Air plasma surface treating is an emerging green technology for leading manufacturers tasked with assembling and decorating plastics, composites, glass and metals. It is a powerful, yet relatively inexpensive technology that is used by both Fortune 100 companies and small operations to improve bond strength, product quality and throughput. You can see the effects of…

Read MoreTop 3 Strategies to Improve Your Adhesive Bonding Operations

Production & design engineers are challenged with developing manufacturing processes that yield optimal results for quality and throughput. Since many do not fully understand the chemistry aspects of interfacial surface adhesion, they rely on conventional production methodologies, which ultimately undermines the repeatability of their success. In this new webinar, industry experts Wilson Lee (Enercon Industries)…

Read MoreIs Plasma Treating the Missing Link in Your Adhesive Bonding Operations?

To enable adhesive bonding, manufacturers rely on primers, cleaners, chemical etching & mechanical roughening. However, these traditional surface preparation methods are notorious for limiting productivity & product quality for the following reasons: Use of in-line plasma & flame surface treating is on the rise because it solves these challenges by cleaning, etching & functionalizing surfaces…

Read MoreSee How Plasma & Flame Treatment Prepare Surfaces for Adhesion

LIVE DEMO REPLAYSee Enercon’s Wilson Lee conduct live demonstrations to display how atmospheric plasma and flame surface treating technologies improve surface energy for improved adhesion of inks, adhesives, & coatings. Topics include: Whether you’re new to surface treating or an industry veteran this presentation has something for everyone. Access to the webinar includes both the…

Read MoreMedical Device Engineer’s Guide for Improving Adhesion with Atmospheric Plasma

As joining of medical plastics is becoming more complex and sophisticated in performance specifications and structural complexity, surface treatment is an integral part of medical assembly processes. This 30-minute webinar, Enercon and BTG Labs provide insights into the capabilities of atmospheric plasma treatment systems and how medical device engineers can use these technologies and surface…

Read More