An Overview of Surface Treatment for Three-Dimensional Objects

If you’ve attempted to print, label, or otherwise decorate a three-dimensional (3-D) product, you’ve probably been frustrated by an ink or adhesive that refused to adhere to the part’s surface. You may have tried different types of ink or adhesive formulations to get the job done, perhaps even used chemical primers or batch-treating processes. Still,…

Read MoreSurface Activation Systems For Optimizing Adhesion To Polymers

Abstract Many experiments have been performed globally to investigate ways of improving adhesion to polymers. This paper discusses current atmospheric surface activation systems, appropriate measurements of wettability and adhesion, over-treatment effects and surface analysis techniques relative to optimizing the adhesion of inks, paints, coatings and adhesives to polymer surfaces. Recommendations for improved activation by substrate…

Read MoreBonding Styrenic Copolymers to Replace PVC

The desire to find a cost-effective, yet environmentally friendly alternative to PVC is the focus of a new technical paper: Bonding Styrenic Copolymers and Thermoplastic Elastomers in the Quest to Replace PVC. The paper details current research on the benefits of using light-curable adhesives and surface treatment technology to optimize bond strength of competitive high…

Read MoreDesign Considerations for Implementing Adhesive Solutions using UV/LED Technologies

Markets for cured adhesives continue to expand as adhesive formulations, materials, & manufacturing processes evolve. In this paper, industry experts discuss the latest technology being used in medical, optics, plastics, and microelectronics for UV/LED cured adhesives. Learn how surface treatment is helping improve the strength of the adhesive and what the most suitable curing solution…

Read MoreEnercon Plasma & Flame Innovations Featured in Special Plastics Report

Plastics Machinery Magazine produced a special report on surface treatment. The publication targeted the most innovative developments in the marketplace and Enercon was pleased to be recognized extensively in two articles for our work in the field of plasma and flame surface treating. Enercon’s plasma and flame surface treating systems are used to clean, etch and functionalize…

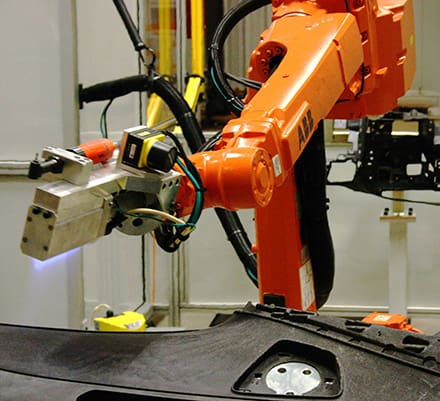

Read MoreAutomation Improves Plasma & Flame Surface Treatment Productivity

The manufacturing of virtually everything from toothbrushes to auto parts can benefit from the use of atmospheric plasma treatment and flame treatment during assembly and decorating operations. These technologies increase material surface energy to promote bonding with inks, adhesives, paints and other coatings. Companies in the medical, automotive, packaging, consumer products, wire & cable, sporting goods, furniture, and others markets find that…

Read MoreImprove Label Adhesion on Bottles – Flame & Plasma Treaters

When packagers are faced with label adhesion challenges, flame and plasma surface treaters are often used to increase bond strength. Label adhesion problems on bottles occur because many of the container, lid and cap materials used in packaging are chemically inert and non receptive to bonding with glue. Options for improving labeling success include changing…

Read MoreWhat Plasma Actually Does to a Surface to Improve Adhesion

Air plasma surface treating is an emerging green technology for leading manufacturers tasked with assembling and decorating plastics, composites, glass and metals. It is a powerful, yet relatively inexpensive technology that is used by both Fortune 100 companies and small operations to improve bond strength, product quality and throughput. You can see the effects of…

Read MoreTop 3 Strategies to Improve Your Adhesive Bonding Operations

Production & design engineers are challenged with developing manufacturing processes that yield optimal results for quality and throughput. Since many do not fully understand the chemistry aspects of interfacial surface adhesion, they rely on conventional production methodologies, which ultimately undermines the repeatability of their success. In this new webinar, industry experts Wilson Lee (Enercon Industries)…

Read MoreImprove Adhesion in Window & Door Manufacturing Processes

Learn how plasma & flame surface treatment are used to efficiently create strong bonds for the assembly, painting and decorating of windows and doors. Discover how these technologies work, see examples of specific industry applications, and get insights from the application experts at Enercon. Plus, gain access to info on our new plasma treating nozzles which are…

Read More