How and why plasma and flame surface treating improve surface adhesion.

Common adhesion impediments found on surfaces. Non-porous and hydrophobic surfaces have low surface energy with few available bonding sites due to low levels of charged ions on the surface. Additionally, any type of surface contamination affects adhesion negatively. This contamination can include material additives & release agents which can migrate to the surface. Clean, Etch…

Read MoreBest Practice for Integrating Plasma & Flame Surface Treaters

In this paper INPRO Technologies Incorporated and Enercon Industries discuss a variety of ways to use plasma or flame for surface preparation. Industries like automotive, aerospace, window and door, assembly, medical, wire & cable, electronics, decorating, and packaging rely on surface treating technologies. Learn about options and considerations for:– Working with flame or plasma– Moving…

Read MoreThree Mistakes to Avoid When Plasma Treating

We have many customers who have tried a corona or plasma treating solution in the past with failed results and were very hesitant to give plasma a second try. However, there are three areas which can be corrected for improved results: using the right plasma technology with the proper set up, having the proper protocols…

Read MoreGetting Started with Flame Plasma

What’s in the eBook? Learn how flame plasma is helping users improve product quality, and increase production speeds. See what Enercon customers are saying “We’ve integrated Enercon flame treaters and we really enjoy working with Enercon because of their depth of knowledge in surface treating.”Jerry Schmit, Sr Applications Engineer, Midwest Engineering Solutions

Read MoreAn Overview of Surface Treatment for Three-Dimensional Objects

If you’ve attempted to print, label, or otherwise decorate a three-dimensional (3-D) product, you’ve probably been frustrated by an ink or adhesive that refused to adhere to the part’s surface. You may have tried different types of ink or adhesive formulations to get the job done, perhaps even used chemical primers or batch-treating processes. Still,…

Read MoreSurface Activation Systems For Optimizing Adhesion To Polymers

Abstract Many experiments have been performed globally to investigate ways of improving adhesion to polymers. This paper discusses current atmospheric surface activation systems, appropriate measurements of wettability and adhesion, over-treatment effects and surface analysis techniques relative to optimizing the adhesion of inks, paints, coatings and adhesives to polymer surfaces. Recommendations for improved activation by substrate…

Read MoreImproving UV Coating Results with Corona & Plasma Surface Preparation

UV coatings are a great choice for high value applications where scratch resistance and surface performance are essential. While traditional UV lamps are still used, the advancement of LED curing technology has improved operational efficiencies for numerous applications. This article reviews the importance of properly preparing surfaces for bonding with a variety of in-line surface…

Read MoreDesign Considerations for Implementing Adhesive Solutions using UV/LED Technologies

Markets for cured adhesives continue to expand as adhesive formulations, materials, & manufacturing processes evolve. In this paper, industry experts discuss the latest technology being used in medical, optics, plastics, and microelectronics for UV/LED cured adhesives. Learn how surface treatment is helping improve the strength of the adhesive and what the most suitable curing solution…

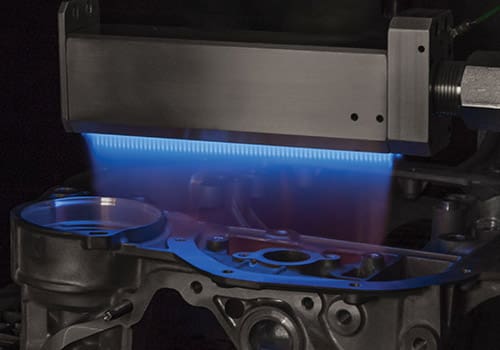

Read MorePlasma & Flame Treatment Prepares Aluminum Surfaces for Bonding

Bonding to aluminum can be major challenge. Engineers typically rely on adhesives to bond aluminum without welding. Depending upon application requirements, there are several adhesives and VHB foam tapes that have proven effective. However, all adhesive-based remedies are subject to failure if surface preparation is overlooked. Aluminum Surface Contaminates Aluminum is often annealed to achieve…

Read MoreAutomotive Parts Supplier Eliminates Hazardous Adhesion Promoter with Enercon Plasma Treating Technology – Saves $850,000, Improves Productivity & Quality while creating a Safer Work Environment.

The integration of an Enercon plasma surface treater into Champion Plastics (Auburn Hills, MI USA) operations will save the company $850,000 on a multi-year project they have with General Motors. The company supplies an injection molded TPV (thermoplastic vulcanizate) seal for a gap in the spoiler of a GM vehicle to improve fuel economy. After…

Read More