Plasma and Flame Surface Treating Demonstration Video for Adhesive Applications

This video features a flame treater integrated with a robot for treating a dashboard prior to protective padding being adhered to it. Blown ion plasma treaters integrated with robotics are shown treating a variety of objects including a plastic assembly, headlamp assembly and a polycarbonate treated to reveal the shape of the Enercon logo.

Read MoreChampion Plastics Adds Enercon Plasma Surface Treater & Helps GM Increase Fuel Efficiency

This remarkable project enabled Champion Plastics to improve operational efficiency and quality, optimize employee utilization and safety and significantly reduce operational costs. When Champion Plastics earned a high-volume program from GM, the company was ecstatic. At the time, they didn’t realize the project would lead them down a path of innovation culminating with a prestigious…

Read MoreSauder Manufacturing Ensures Adhesion Consistency with Corona, Plasma & Flame Surface Treating

As Sr Research Scientist at Sauder Manufacturing in Archbold, OH John Beck has seen his share of production challenges. His first experience with surface treating took place in the 1980s when he was part of a team that needed to improve lamination adhesion. They invested in a 66” wide Enercon corona treater to increase the…

Read MorePlasma and Flame Surface Treating Enable Automotive Adhesive Bonds

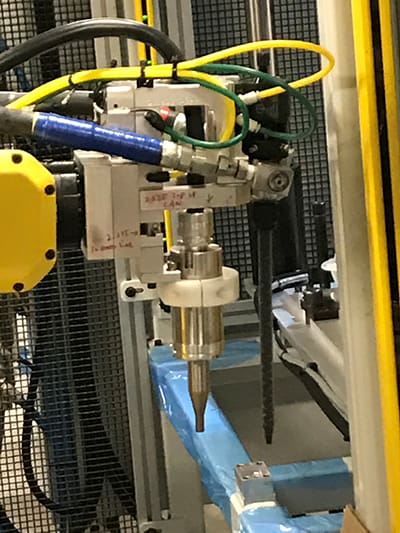

TA Systems of Rochester Hills, Michigan, specializes in engineering custom automation solutions for the automotive industry. Their customers rely on them to integrate multiple technologies and processes into efficient manufacturing cells. Recently, there has been an increase in requirements for integrated in-line surface treating to improve adhesive bonding on a variety of plastics. While at…

Read MorePlasma Treating Tubes Ensures Ink Adhesion and Increases Production Efficiency

Plastube is a Canadian manufacturer of innovative plastic tubes for the beauty, healthcare, food and pharmaceutical industries. The company produces and prints polyethylene tubes, tubes with an inner foil and exterior plastic and laminate tubes. Their mission is to make their customers’ brands shine. Package appearance for tubes sold in the retail marketplace is vitally…

Read MoreAtmospheric Plasma Treater Increases Folder Gluer Production

When new technology can improve product quality, increase productivity and offer additional cost reductions at an affordable investment, it doesn’t take long for a company to incorporate it into their operation. Such is the case for Green Bay Packaging’s Folding Carton Division (De Pere, WI) and their new atmospheric plasma surface treater. Green Bay Packaging is an…

Read MorePlasma Surface Treating Improves Composite Surface Bonding Over Peel-Ply and Hand Prep

Composites offer design engineers remarkable strength and corrosion resistance without the burden of excess weight. It’s no wonder that these properties make them very popular choices in the automotive, aerospace, and marine industries. They are ideal for lightweight energy efficient products without sacrificing safety or performance. Manufacturers of these products are faced with the challenges…

Read More