Enercon Unveils Plasma & Flame Surface Treating Laboratory to Advance Adhesion Innovation

Enercon proudly announces the opening of its new Surface Treating Laboratory, a cutting-edge facility designed to demonstrate and develop the latest advancements in atmospheric plasma and flame surface treatment. “As the surface treating technology leader, Enercon offers the industry’s greatest variety of Blown-arc™, Blow-ion™ & Multiport™ plasma & flame surface treaters. With this new lab,…

Read MoreChoosing the Best Surface Treatment Technology: Plasma vs. Flame

Surface treatment technologies, including plasma and flame, play a pivotal role in enhancing adhesion, improving surface energy, and enabling efficient and repeatable manufacturing processes. Choosing between these technologies depends on the materials being treated, application speed, and system integration. In this guide, we’ll break down the key differences, benefits, and practical considerations to help you…

Read MorePrevent Adhesion Related Warranty Claims with Plasma & Flame Surface Treatment

Failed adhesion costs manufacturers millions of dollars in warranty claims every year. The root cause is often inadequate surface preparation. In this new webinar, find out how leading automotive manufacturers solve adhesion-related warranty issues by improving their production processes with plasma & flame. Insights for Webinar Attendees: Find out how you can determine if automating…

Read MoreEverything You Need To Know About Flame Surface Treatment

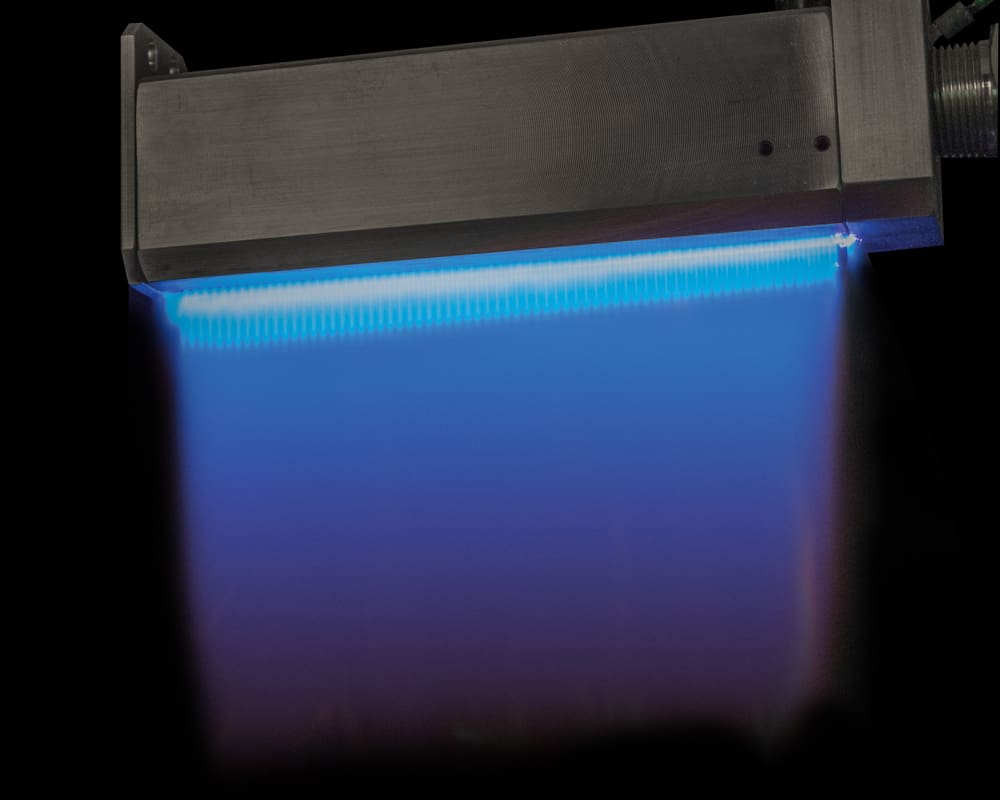

The Key to Stronger, More Reliable Adhesive Bonds: Flame Treatment One of the most important requirements for adhesion is the condition of the surface prior to bonding with inks, coatings and adhesives. Fortunately, there are technologies which can be used to modify surfaces to make them more receptive to bonding. One of the oldest surface…

Read More5 Mistakes to Avoid When Plasma or Flame Treating Surfaces

When properly implemented, plasma and flame surface treating can improve bonding with adhesives, coatings and inks. However, there are a number of common mistakes made when evaluating and integrating surface treaters that can easily be avoided. In this new webinar, Enercon shares insights on mistakes that can undermine your success: Fill out the form to…

Read MoreNew Plasma & Flame Treater Head Designs Improve Treatment Coverage, Integration and Efficiency

Manufacturers look to Enercon to solve adhesive, ink & coating challenges. Many of these applications require a unique or custom engineered solution. This is where our plasma & flame treating experts work their magic. In this exclusive webinar, we share our most recent groundbreaking surface treater designs that enable plasma & flame to overcome integration…

Read MoreEnercon Offers the Widest Range of Surface Treating Technologies at NPE

Get your chance to see the industries’ most comprehensive platform of PLASMA, FLAME & CORONA surface treating technologies in the FRONT ROW of NPE’s West Hall (Booth W6643). (Get your free pass using code 47342.) Object Treating Technologies & Applications Witness plasma treating in action & how it improves surface adhesion on all types of…

Read MoreMyths and Mysteries of Measuring Dynes, Surface Free Energy & Contact Angle

Since plasma and flame surface treatment create no visible changes to a surface, methodologies have been developed to measure the changes to a surface after treatment. These diagnostics are quite valuable, but they are often conducted with flawed testing practices and the results are frequently misunderstood. In this new webinar, experts from Enercon & KRÜSS…

Read MorePlasma, Flame & Corona Pretreatment for Surface Treating Plastics

Generally, plastics have chemically inert and nonporous surfaces with low surface tensions. This makes them nonreceptive to bonding with inks, adhesives, coatings, and other substrates. Polyethylene and polypropylene for example have very low surface energy. Pretreatment of these and other engineered plastics improves bonding prior to printing, coating, and laminating. The best type of surface…

Read MorePlasma & Flame Surface Treatment Distance & Dwell Time Recommendations for Consistent Treatment Results

What is the ideal distance between the treatment head and the surface to be treated? The answer depends on the surface treater you are using and your specific application. However, there are some general guidelines that you should be aware of: Treatment Distance Treatment Dwell Time Treatment Angle Measuring Treatment Success Pretesting and good documentation…

Read More