Automation Improves Plasma & Flame Surface Treatment Productivity

The manufacturing of virtually everything from toothbrushes to auto parts can benefit from the use of atmospheric plasma treatment and flame treatment during assembly and decorating operations. These technologies increase material surface energy to promote bonding with inks, adhesives, paints and other coatings. Companies in the medical, automotive, packaging, consumer products, wire & cable, sporting goods, furniture, and others markets find that…

Read MoreImprove Label Adhesion on Bottles – Flame & Plasma Treaters

When packagers are faced with label adhesion challenges, flame and plasma surface treaters are often used to increase bond strength. Label adhesion problems on bottles occur because many of the container, lid and cap materials used in packaging are chemically inert and non receptive to bonding with glue. Options for improving labeling success include changing…

Read MoreContinuous Inkjet Printing for Industrial Manufacturing Applications

As a non-contact printing process, inkjet offers manufacturers tremendous production advantages including variable data, fast changeover and reliability at top line speeds. Applications abound for plastics and rubber in the wire & cable, packaging, coding & industrial manufacturing industries. However material properties, surface contamination, ink/material compatibility and durability requirements create challenges. Keys for successful ink…

Read MoreWhat Plasma Actually Does to a Surface to Improve Adhesion

Air plasma surface treating is an emerging green technology for leading manufacturers tasked with assembling and decorating plastics, composites, glass and metals. It is a powerful, yet relatively inexpensive technology that is used by both Fortune 100 companies and small operations to improve bond strength, product quality and throughput. You can see the effects of…

Read MoreHow Plasma Treating is Your Best Adhesion Insurance Against Disruptive Supply Chains

When supply chain issues force you to use alternate suppliers and/or replacement materials, you may end up opening a Pandora’s Box of hydrophobic production issues. Water-based and UV inks and adhesives need hydrophilic surfaces for successful bonding. Subtle changes in surfaces and chemistries can quickly disrupt assembly and decorating operations. In this new webinar, learn…

Read MoreTop 3 Strategies to Improve Your Adhesive Bonding Operations

Production & design engineers are challenged with developing manufacturing processes that yield optimal results for quality and throughput. Since many do not fully understand the chemistry aspects of interfacial surface adhesion, they rely on conventional production methodologies, which ultimately undermines the repeatability of their success. In this new webinar, industry experts Wilson Lee (Enercon Industries)…

Read MoreImprove Adhesion in Window & Door Manufacturing Processes

Learn how plasma & flame surface treatment are used to efficiently create strong bonds for the assembly, painting and decorating of windows and doors. Discover how these technologies work, see examples of specific industry applications, and get insights from the application experts at Enercon. Plus, gain access to info on our new plasma treating nozzles which are…

Read MoreIs Plasma Treating the Missing Link in Your Adhesive Bonding Operations?

To enable adhesive bonding, manufacturers rely on primers, cleaners, chemical etching & mechanical roughening. However, these traditional surface preparation methods are notorious for limiting productivity & product quality for the following reasons: Use of in-line plasma & flame surface treating is on the rise because it solves these challenges by cleaning, etching & functionalizing surfaces…

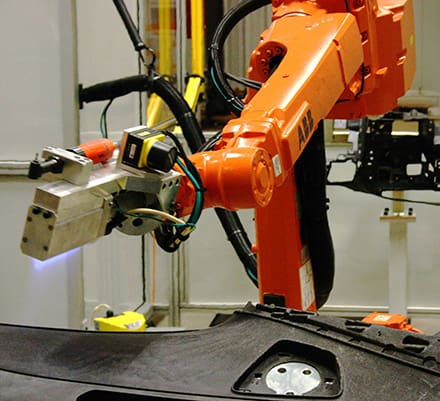

Read MoreHow Automotive Manufacturers use Plasma & Flame to Improve Quality & Efficiency

Plasma & Flame surface treating technologies are helping suppliers in the automotive industry reduce cost, improve quality, and maximize production efficiencies. Projects for vehicle lightweighting, decorating, gasket sealing adhesion, and electrical potting are fueling the need for incorporating plasma and flame surface treaters. This 45-minute webinar provides insights on how treatment improves adhesion for assembling,…

Read MoreTechnology Demos: Plasma & Flame Surface Treating for Improved Adhesion

See how surface treating technologies work in this new webinar featuring equipment in action. Watch how Blow-ion™, Blown-arc™ and Power Flame™ surface treatment is created through narrated animations and videos. In this webinar, hosted by surface treating expert Wilson Lee, attendees gain insights on the reasons manufacturers rely on each of these technologies to improve…

Read More