Clean is good, but is it good enough for successful adhesion?

Smart manufacturers recognize the importance of a clean surface when bonding components. If a part is not clean, the adhesive will bond to the surface contamination rather than directly to the surface itself. Manufacturers commonly use a solvent to clean the surface. However, this isn’t always enough to produce the desired adhesive outcome. A clean…

Read MoreRoll Aluminum Surface Preparation for Packaging Applications

The packaging industries within North America and Western Europe consume the majority of the aluminum sheet and foil for making beverage cans, flexible packaging and foil wraps. The choice of alloy for these applications typically predetermines properties such as strength, formability and resistance to corrosion. Other requirements such as the surface finish, flatness and gauge…

Read MoreAtmospheric Surface Modification Of Polymers For Biomedical Device Adhesion

Abstract Biomedical applications require polymers that react properly with the biological environment in which they are employed. Since biocompatibility involves the interface between the device and the biological environment, surface modification techniques can be critical to solve adhesion issues, avoiding costly changes of materials. Atmospheric surface modification techniques such as air plasma, flame plasma and…

Read MoreDesmear & Descum Circuit Boards with Plasma Treatment

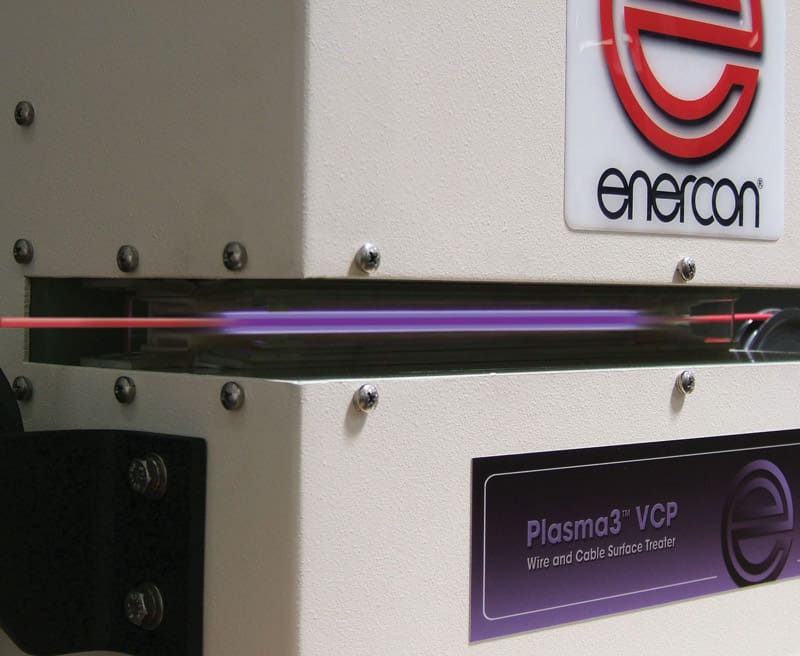

Complex printed circuit board constructions with ever-increasing layers and circuit densities benefit from Plasma3™ plasma treatment for descum, desmear, removal of carbon-based organics, PTFE activation, and surface preparation. Plasma processing of various board types historically have used vacuum plasma technologies. However, there is a need for increased processing capacities as the printed circuit board construction continue to…

Read MoreHow and why plasma and flame surface treating improve surface adhesion.

Common adhesion impediments found on surfaces. Non-porous and hydrophobic surfaces have low surface energy with few available bonding sites due to low levels of charged ions on the surface. Additionally, any type of surface contamination affects adhesion negatively. This contamination can include material additives & release agents which can migrate to the surface. Clean, Etch…

Read MoreAtmospheric Plasma and Flame Surface Treatment for Medical Applications

Get insight on how medical device manufacturers are using atmospheric plasma to eliminate adhesion challenges. What’s in the eBook? Learn how atmospheric plasma is helping users improve product quality, and increase production speeds. See what Enercon customers are saying “For medical printing applications, it’s imperative to follow the defined protocols. Enercon’s experience with medical device…

Read MoreAn Overview of Surface Treatment for Three-Dimensional Objects

If you’ve attempted to print, label, or otherwise decorate a three-dimensional (3-D) product, you’ve probably been frustrated by an ink or adhesive that refused to adhere to the part’s surface. You may have tried different types of ink or adhesive formulations to get the job done, perhaps even used chemical primers or batch-treating processes. Still,…

Read MoreSurface Activation Systems For Optimizing Adhesion To Polymers

Abstract Many experiments have been performed globally to investigate ways of improving adhesion to polymers. This paper discusses current atmospheric surface activation systems, appropriate measurements of wettability and adhesion, over-treatment effects and surface analysis techniques relative to optimizing the adhesion of inks, paints, coatings and adhesives to polymer surfaces. Recommendations for improved activation by substrate…

Read MoreImproving UV Coating Results with Corona & Plasma Surface Preparation

UV coatings are a great choice for high value applications where scratch resistance and surface performance are essential. While traditional UV lamps are still used, the advancement of LED curing technology has improved operational efficiencies for numerous applications. This article reviews the importance of properly preparing surfaces for bonding with a variety of in-line surface…

Read MoreDesign Considerations for Implementing Adhesive Solutions using UV/LED Technologies

Markets for cured adhesives continue to expand as adhesive formulations, materials, & manufacturing processes evolve. In this paper, industry experts discuss the latest technology being used in medical, optics, plastics, and microelectronics for UV/LED cured adhesives. Learn how surface treatment is helping improve the strength of the adhesive and what the most suitable curing solution…

Read More