Manual & Sheetfed Sheet Treaters

Enercon corona sheet treaters offer sheet converters the in-house ability to treat a wide variety of non-porous polymer based materials and synthetic papers. These material types have inert and low surface energy preventing inks from properly adhering. In-line sheet treatment ensures successful printing by raising the substrate's surface energy to allow inks to properly wet-out.

Pretreatment is ideal for any sheet printing process including lithography, UV, EB and Screen Printing. Common materials that require treatment include Polystyrene (PS), Polyvinylchloride (PVC), Polyethylene (PE), Polypropylene (PP), Polycarbonate (PC), and Polyester (PL). Enercon's treatment technology is effective at treating leading synthetic materials including Teslin®, Kimdura®, Polyart® and Yupo®.

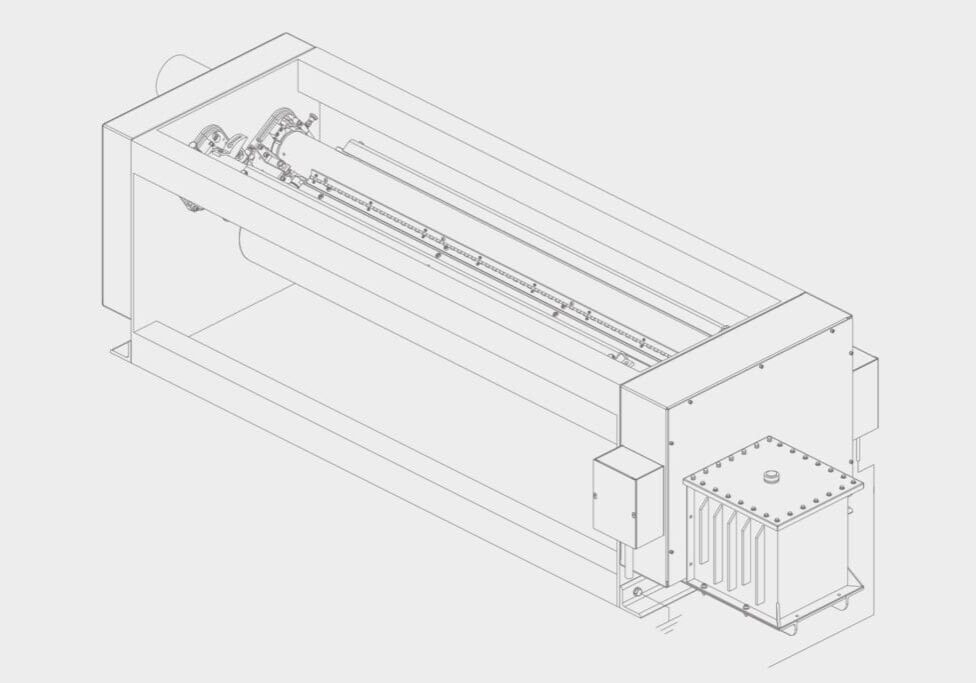

Manually-Fed Sheet Treater

Enercon’s Sheet Treater is designed for operations requiring an economic corona treatment solution that reliably treats substrates for cleaning and increasing surface energy. Corona treat any sheet - plastic, foil, metalized film, nonwovens, synthetic materials and paper.

Operation Modes:

- Manual Mode - set the Power Level, Speed and Number of Passes.

- Watt Density Mode - set the Watt Density & Speed. The system will automatically calculate the Power Level and the Number of Passes required to meet the treatment requirement.

System Features

Industrial Construction

- Powder-coated steel, stainless steel, aluminum and ozone-resistant components

Sheet Handling

- Vacuum table with stainless steel vacuum plate

Corona Electrode Assembly

- High-powered and reliable ceramic electrodes

- Ozone removal and electrode cooling assembly

- Variable speed electrode assembly drive

- Timing belt drive for smooth operation

Integrated Features

- Color touch screen for control of all parameters

- Power Supply and HV Transformer

- Duct connection for exhaust with air flow switch

System Options

- Vacuum & Exhaust Blower

- Ozone Decomposer

- Light Curtain

| Max Sheet Dimensions | ||||

|---|---|---|---|---|

| Inches | 12" X 18" | 20" X 24" | 22" X 46" | |

| mm | 304.8 x 457.2 | 558.8 x 1168.4 | 508 x 609.6 | |

Enercon systems are designed to operate in a maximum ambient temperature of 40°C (104°F) @ 80% relative humidity, non-condensing.

KEY FEATURES Cleaning & Increasing Surface Energy

-

Applications

- Point of sale (POS) signage

- Labels

- Decals

- Tags

- Folders

- Lab-based material test results

- Countless other packaing applications

- Research & Development

CORONA TREATING POWER SUPPLIES

Reliable industry workhorse for basic applications

Proven Reliability with Advanced Features

OPTIONAL EQUIPMENT Which may be recommended or specified:

-

Network Communication

-

Ozone Decomposer

-

Quick Disconnect Electrode Cartridge

-

Spare Electrodes

-

Spare Parts Kit

-

Start-up Assistance

-

Station Guarding