Surface Treating Insights for Substrates Used in Lithium-ion Battery Production

The global demand for high performing Lithium-ion and Electric Vehicle batteries is on the rise. Many of the foil and polymer film substrates used for these applications require surface treatment to enable proper coating adhesion and battery performance. Many innovators in this market rely on Enercon’s surface treating laboratory as the proving ground for optimizing…

Read MoreHow Bump Corona Treating Improves Laminating, Coating & Printing

Whose responsibility is it to make sure a film is ready to be converted? Film supplier or Converter? Depending on what part of the world you are in this question can spark an inspired debate. Both the film supplier and the converter are in business to make money. When printing, coating & laminating applications go…

Read MorePattern Corona Treating Offers Flexibility for Pouches & Bags

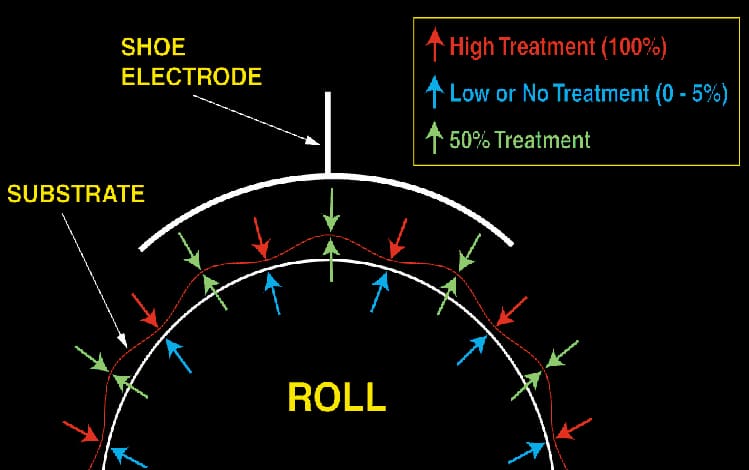

Corona treatment is widely used by flexographic printers to control surface energy for successful ink adhesion. In most cases, treating the entire width of the web is required. However applications requiring selective treatment are becoming more popular. Printing Stand-up PouchesStand-up pouches are made up of non-porous barrier films which require treatment prior to printing. However, corona…

Read MoreCoating Adhesion for Films with Corona, Flame & Plasma

Successfully applying a high quality, continuous web coating requires advanced and versatile technologies which can effectively meet the varied needs for films. Surface treatment plays an important role in this process. The properties of the substrate are therefore absolutely critical to ensure good coating quality and product performance. The substrate needs to be uniformly wetted…

Read MoreWhy All Films Do Not Treat the Same

The Signature Relationship Between Your Film and Corona Treaters How well do you understand the relationship between your films and your corona treater? A treatment level of 2.0 watt density yields very different results on PET compared to Polypropylene. And, a nominal change in watt density can produce unexpected results. This paper looks at the…

Read MoreWhy do I need corona treating and how do corona treaters work?

Corona treating increases the surface energy of plastic films, foils and paper to improve wettability and adhesion of inks, coatings and adhesives. Treating works best when a substrate is treated at the time of extrusion and in-line prior to converting. Corona treating increases quality and productivity through improved print quality, faster press speeds and less…

Read MoreSolving Metallized Film Converting Adhesion Issues

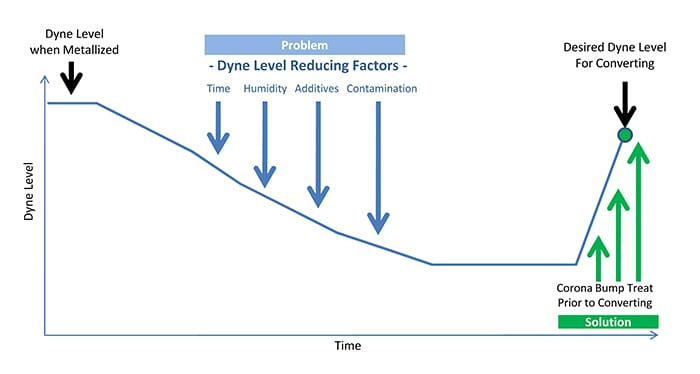

Most application questions involving the converting of metallized films concern the dyne level required to convert. It is extremely important for both the film manufacturer and the converter to recognize that achieving a specific dyne level does not guarantee printing, coating or laminating adhesion. Most converters will conduct a dyne test on metallized film prior…

Read MoreSolvent-Based Printing Improved with Corona Treatment

Enercon has the fortunate opportunity to share ideas with solvent-based printers from around the globe on an almost daily basis. To say the world of printing has changed in the last 15 years is an understatement. More complex film compositions, more intricate graphic designs, shorter press runs, faster production speeds, greater scrutiny with higher expectations…

Read MorePrevent Backside Treatment

The bad news is that backside treatment mitigates the effects of surface treating. In some cases, it results in under treatment of substrates. It can also raise the energy of the backside surface creating processing problems. In bag making and seal applications, backside treatment can alter the substrate’s co-efficient of friction. This will ultimately cause…

Read MoreExtrusion Coating Bonding Success Improved with Surface Treating

Chances are you or someone you know has a secret family recipe for a great barbecue sauce, or chili or killer cheesecake. In each case, there’s probably a unique combination of ingredients that makes all the difference in the world. As a professional in the extrusion industry, you can probably relate the family recipe analogy…

Read More