Next Generation Corona Treaters: How Smart New Features Will Make Your Operation More Profitable

Start/Stop. Power Up/Down. Who could ask for more? Well, you should; and now Enercon is making it possible. To compete at a high level, you need the right technology to support your operation. We’re talking about innovative systems that do the thinking for you. Enercon’s design engineering team has developed leading edge technology to take…

Read MoreCorona Treater Installation Best Practices: Prevent Downtime

When properly installed, maintained and operated, corona treaters are one of the most reliable pieces of equipment on your line. But did you know that over half of corona treater downtime is associated with mistakes made during the installation of the original equipment? This means that 50% of corona treater downtime is easily preventable. Symptoms…

Read MoreTrends For Integrating Corona Treaters on Flexographic Printing Presses and Laminators

Gain a clear understanding of corona treater integration on Flexographic Printing Presses and Laminators. In this webinar we will review: Access both a video presentation and pdf of the presentation through the form to the right. Innovative People Ensuring Your Treating Success. Enercon is a global leader in surface treatment technology. Our innovative team of…

Read MoreOptimal Blown Film Line Layout for Surface Treatment

When it comes to surface treatment on a blown film line, there are a number of different philosophies employed. Factors including budget, available space, and specific application criteria all contribute to your ultimate decision. Because of these variables, it’s understandable that if I asked ten film extruders how they set-up the surface treatment section of…

Read MoreCorona Treating Installation Planning Saves Money and Time

An accurate cost assessment of any piece of converting equipment ought to include a review of installation cost. Proper planning will eliminate avoidable variables that create project delays, allow installation costs to soar, and weigh heavily on your peace of mind. Many Enercon customers are quite proactive in working with our engineers to ensure the…

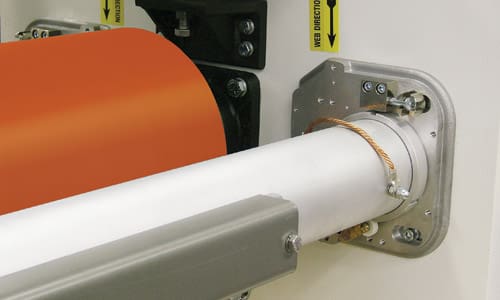

Read MoreClearing the air on the gap between ceramic coated ground rolls and their bare roll predecessors.

Years ago, corona treating technology was pretty simple and straightforward. There were two types of corona treating systems to choose from: Covered Roll systems and Bare Roll systems. Since that time ceramic coated ground rolls have revolutionized bare roll systems. These systems have become popular because they provide more power than their predecessors and also eliminate common problems associated with…

Read MoreCorona Treater Station Design & Construction: Meeting The Converting Challenge

Abstract Treater station construction has undergone significant modification to accommodate rapid change in converting applications: lighter webs, higher line speed operation and advanced substrates (e.g., co-extruded, metallized and very thin substrates). This range of developments has introduced the requirement for nips at the treater roll, using the treater roll as a “pull roll” and modifying…

Read More