Improve Print Quality & Productivity by Controlling Substrate Surface Energy

Poor ink adhesion affects print quality, creates downtime, and leads to lost customers. In many cases, the cause is rooted in complications from the substrate surface. The good news is that surface variables can be eliminated with the proper use of a corona treater. A common misunderstanding is that pretreated films eliminate the need for…

Read MorePurged surface treater safely allows solvent printers to run faster and reduce costs.

Solvent-based printers are recognizing the benefits of surface treating and Enercon has specifically designed a surface treater to meet their solvent printing needs. The system puts quality control in the printers’ hands by ensuring optimal substrate surface energy. Materials with higher surface energy may require a secondary (or “bump”) corona treatment of the substrate to…

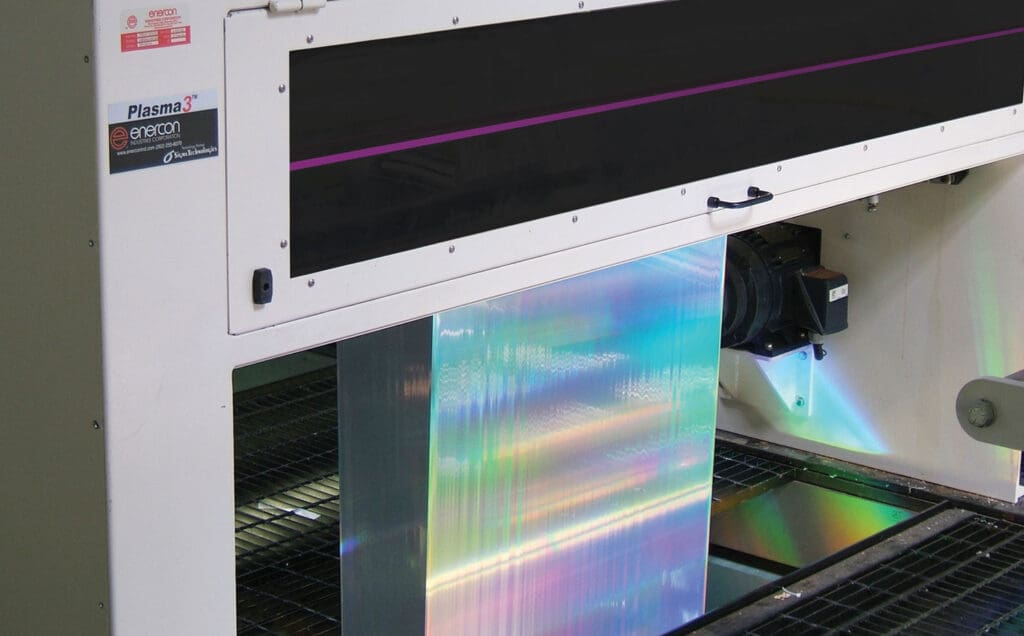

Read MoreMetallized Film Adhesion: Processing & Converting with Surface Treatment

Metallized film presents adhesion challenges to both film suppliers and converters. Today, new developments in surface treatment are creating competitive advantages by extending surface energy stability on metallized film. What metallized film converters should know Both the metallized film supplier and converter are at the mercy of the physics involved with dyne levels. Dyne level…

Read MoreImprove Lamination Adhesion with Surface Treating

For many industrial applications, the use of a single ply of a material does not provide all of the critical properties required for the optimal performance of a product. In these cases, a composite of two or more layers of material can provide this required performance. A common method of creating such a composite is…

Read MoreImprove Ink Printing Adhesion with Surface Treating

The task of optimizing printing adhesion can be difficult, primarily because of the many process variables which require control. The most critical of these parameters are 1) ink chemistry, 2) substrate quality, 3) surface treatment, and 4) ink transfer method. There are six major printing/decorating processes, each distinguished by the method in which ink and…

Read MoreGetting Started with Corona Surface Treatment

This free eBook shares expert insights from Surface Treating Experts. Discover how Converters & Extruders use Corona Treating to Improve Adhesion Corona treating improves a film’s receptiveness to inks, coatings, and adhesives. In this informative eBook, you’ll find insights on how corona treating works, application examples and considerations when specifying corona treaters. See what Enercon…

Read MoreMeasuring Surface Energy On Non-Woven Substrates

There is no easy way to determine changes in surface energy on non-woven and woven substrates and we know of no official standards such as an ASTM method but there is a procedure. There are several methods to characterize the surface energy of nonwovens fibers. Of these, contact angle is the most readily applied. One…

Read MoreRecommended Surface Energy & Treatment Ranges for Printing & Coating Polymer Surfaces

We’re often asked what dyne level do I need to print on a particular type of film. Its a complex question that includes many variables beyond the material type and method of printing or coating. We can however provide general guidelines that you can use to start your own evaluations. The tables below list general…

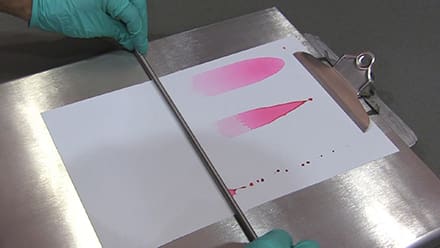

Read MoreUsing Dyne Solutions and Dyne Pens to Measure Surface Energy On Non-Porous Substrates

Non-porous substrates, such as polyethylene, polypropylene and foils, need to have their surface energies altered in order for the proper flexographic ink adhesion to occur. An old general rule of thumb is that the substrate should have a dyne level (surface-energy measurement) of at least 10 dynes higher than the surface energy of the ink…

Read MoreTruth or Dyne? How to Properly Conduct Dyne Tests & What Your Results Really Mean

Corona treaters are used to increase a film’s surface energy to enable wettability & promote the adhesion of inks, coatings and adhesives. This change in surface energy is most commonly measured in dynes. And that’s where problems for extruders and converters begin. Poorly executed dyne tests produce unreliable results and assumptions about dyne levels lead…

Read More