Surface Treating for Extrusion Coating

Increase surface energy for printing

Extrusion coating processes benefit from surface treating in many areas. Polymer films are often corona treated at the primary and secondary unwinds prior to the extrusion coating process.

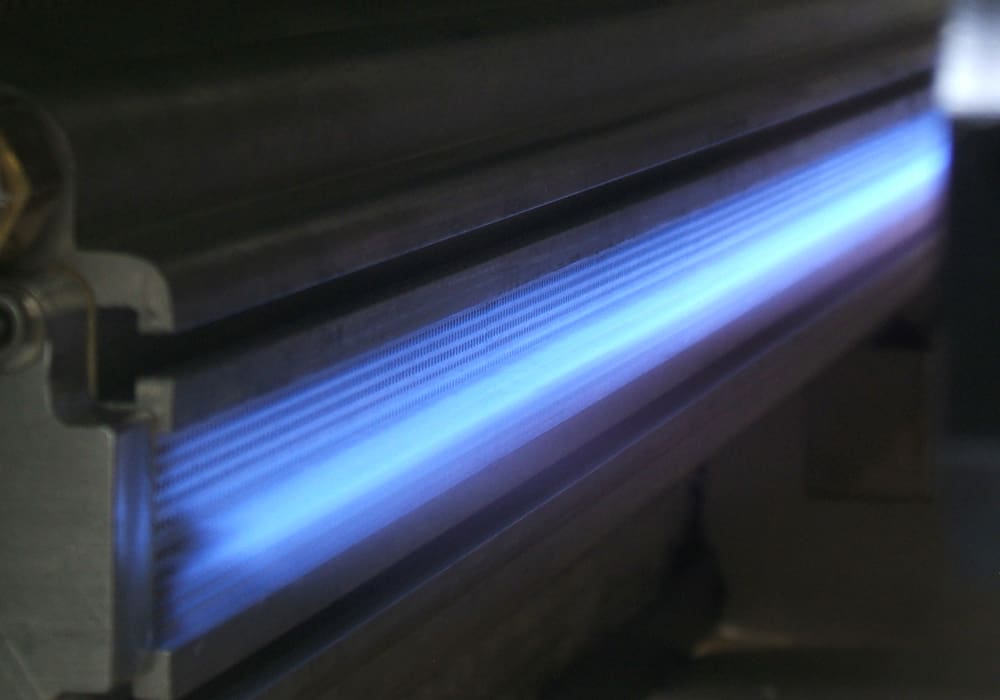

Flame treatment is used with high speed paperboard applications. Corona treating is also used as a post treater to enable additional converting of the coated film.

Many extrusion coating operations are finding significant benefits in introducing ozone at the nip of the film and extrudate. Ozone treatment on extrusion coating lines can improve bonding adhesion, enable lower extrudate temperatures, and promote higher line speeds.

Enercon application engineers can help you determine which surface treating solutions will work best for your specific application.

Contact us for more insights on corona treating for your extrusion coating operation or learn more by following the links below.

FROM OUR LIBRARY Insights on Surface Treating & Extrusion Coating

WIDELY USED In Extrusion Coating

-

Corona Benefits

Primary, Pre & Post Treatment

-

Flame Benefits

Treat Kraft paper board at high speeds

-

Ozone Benefits

Better adhesion, faster line speeds, lower melt temperature, reduced odor, & extrudate air gap

-

Plastic Films

-

Paperboard

-

Aluminum Foils

-

Flexible Packaging

-

Aseptic Packages