Corona Treating Improves Ink Adhesion for Printing

Increase surface energy for printing

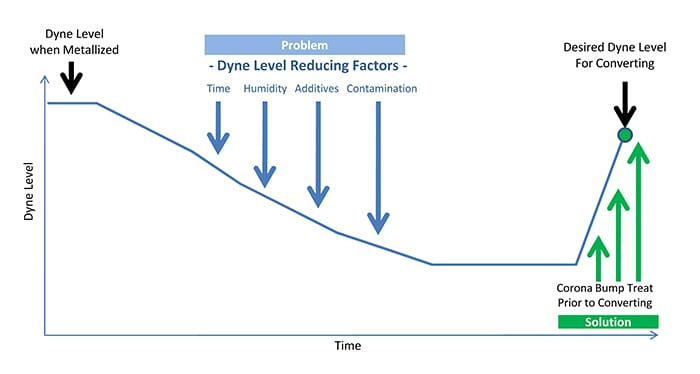

Flexographic, gravure and digital printing inks require a clean and compatible surface for bonding. When inks fail to bond properly with a surface it is often because of low surface energy or surface contamination.

Corona treaters are integrated in-line on printing presses and digital printers to remove contamination, increase surface energy and provide a surface suitable for printing. Printers using water based, solvent based and UV inks benefit from adding in-line bump treatment to their lines. Operations that use corona treaters maximize print quality, line speed and uptime.

Corona treatment is effective on all types of plastic and metallized films, label stock and non wovens. Enercon manufacturers corona treaters for narrow web printing and high definition corona treaters for wide web printing.

FROM OUR LIBRARY Insights on Web Printing

Web Surface Treating & Ink Adhesion Common Printing Applications:

-

Bags

-

Flexible Packaging & Pouches

-

Food Packaging

-

Tags & Labels

-

Solvent Based Inks

-

Water Based Inks

-

UV Inks

-

Digital Printing

-

Flexographic Printing

-

Gravure Printing

-

PE, PET, HDPE, LDPE

-

BOPP, CPP, PP, OPP

-

Coated Paper Board

-

Metallized Films, Nonwovens & More