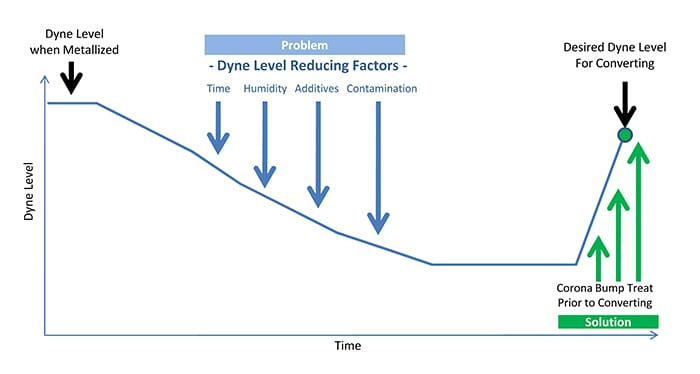

How Bump Corona Treating Improves Laminating, Coating & Printing

Whose responsibility is it to make sure a film is ready to be converted? Film supplier or Converter? Depending on what part of the world you are in this question can spark an inspired debate. Both the film supplier and the converter are in business to make money. When printing, coating & laminating applications go…

Read MoreMaintain or reinvest in a corona treater? What’s a converter to do?

Can you afford to maintain your old surface treater? Your organization has probably seen its share of downsizing. And your resources are spread about as thin as can be. As you look to do more with less it can be a difficult time to justify an investment in new equipment. But how much is that…

Read MoreWhen to replace an old corona treater power supply

If your company has been around for twenty years or longer, chances are you have some older equipment in your plant that may be nearing the end of its useful life. Since replacing an entire corona treater system can be a sizable investment, many companies opt to replace the power supply first. Since electronic equipment becomes obsolete…

Read MoreWhy All Films Do Not Treat the Same

The Signature Relationship Between Your Film and Corona Treaters How well do you understand the relationship between your films and your corona treater? A treatment level of 2.0 watt density yields very different results on PET compared to Polypropylene. And, a nominal change in watt density can produce unexpected results. This paper looks at the…

Read MoreWhich Surface Treating Technology is Best for my Application?

Corona, Plasma or Flame? Surface treating in the converting industry is used to improve the adhesion of engineered films and foils that would otherwise be unreceptive to bonding with inks, coatings, and adhesives. As the only industry supplier who manufactures corona, plasma and flame treatment technologies, Enercon Industries Corporation offers unique insights on how these…

Read MoreProper Dyne Testing Methods: Buddy, Can You Spare a Dyne?

Dyne Tests Only Work When You Do Them Right Dynes are used to measure changes in a film’s surface energy. But poorly executed dyne tests produce unreliable results. And false assumptions about dyne levels, adhesion and corona treating leads to major problems. This insightful technical paper reviews best practices for dyne pen, cotton swab, and…

Read MoreTAPPI Mayer Rod Drawdown Dyne Testing

The Mayer Rod Drawdown Method is an industry standard under TAPPI Test Method T 552: Determination of Wetting Tension of Polyolefin Films and Coated Surfaces via the Mayer Rod Technique. How to apply:A substrate sample, usually measuring 8-1/2 x 11 inches, is clamped to a clipboard. At the top of the sample, a single drop…

Read MoreASTM Cotton Swab Dyne Testing

The Cotton Swab Method is recognized as an industry standard under ASTM D2578-17, Standard Test Method for Wetting Tension of Polyethylene and Polypropylene Films. Dyne solutions of various concentrations are placed on the substrate until a solution is found that wets out properly. How to apply:Drops of a dyne test solution are placed on the tip…

Read MoreWhy do I need corona treating and how do corona treaters work?

Corona treating increases the surface energy of plastic films, foils and paper to improve wettability and adhesion of inks, coatings and adhesives. Treating works best when a substrate is treated at the time of extrusion and in-line prior to converting. Corona treating increases quality and productivity through improved print quality, faster press speeds and less…

Read MoreHigh Performance PVD and PVDF Films Benefit from High Definition Corona Treatment

PVD (polyvinylidene) and PVDF (polyvinylidene difluoride), also known as brand names Tedlar® and Kyner®, are films with remarkable capabilities for a variety of applications. From release liners to spaceship bio barriers, these films offer purity and strength while resisting solvents, acids, and heat. These films are used in battery, aerospace, architectural, solar, printed circuit boards,…

Read More