Why do I need corona treating and how do corona treaters work?

Corona treating increases the surface energy of plastic films, foils and paper to improve wettability and adhesion of inks, coatings and adhesives. Treating works best when a substrate is treated at the time of extrusion and in-line prior to converting. Corona treating increases quality and productivity through improved print quality, faster press speeds and less…

Read MoreTroubleshooting Surface Treating for Flexographic Printing Process

Want to learn more about your flexographic printing process? Want your operators to have more control over the press? Then learn the power of asking “why”. Three letters that add up to a powerful and revealing question. When we were three and four years old, it was our favorite question. It often stymied Mom and…

Read MoreSolving Metallized Film Converting Adhesion Issues

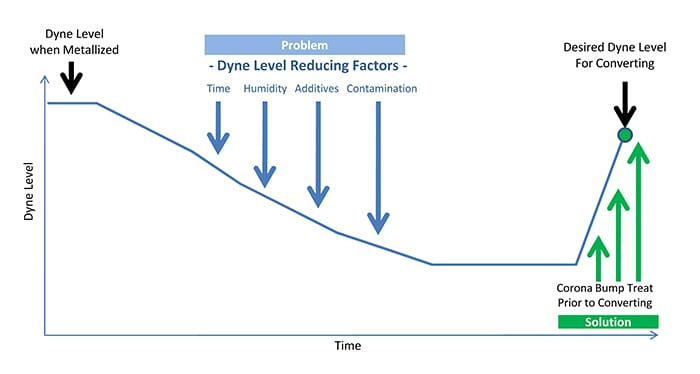

Most application questions involving the converting of metallized films concern the dyne level required to convert. It is extremely important for both the film manufacturer and the converter to recognize that achieving a specific dyne level does not guarantee printing, coating or laminating adhesion. Most converters will conduct a dyne test on metallized film prior…

Read MoreSolvent-Based Printing Improved with Corona Treatment

Enercon has the fortunate opportunity to share ideas with solvent-based printers from around the globe on an almost daily basis. To say the world of printing has changed in the last 15 years is an understatement. More complex film compositions, more intricate graphic designs, shorter press runs, faster production speeds, greater scrutiny with higher expectations…

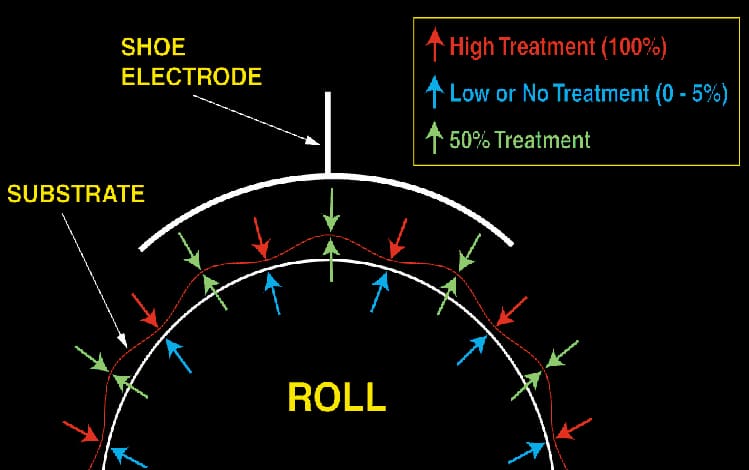

Read MorePrevent Backside Treatment

The bad news is that backside treatment mitigates the effects of surface treating. In some cases, it results in under treatment of substrates. It can also raise the energy of the backside surface creating processing problems. In bag making and seal applications, backside treatment can alter the substrate’s co-efficient of friction. This will ultimately cause…

Read MoreHigh Performance PVD and PVDF Films Benefit from High Definition Corona Treatment

PVD (polyvinylidene) and PVDF (polyvinylidene difluoride), also known as brand names Tedlar® and Kyner®, are films with remarkable capabilities for a variety of applications. From release liners to spaceship bio barriers, these films offer purity and strength while resisting solvents, acids, and heat. These films are used in battery, aerospace, architectural, solar, printed circuit boards,…

Read MoreCorona Treating Installation Planning Saves Money and Time

An accurate cost assessment of any piece of converting equipment ought to include a review of installation cost. Proper planning will eliminate avoidable variables that create project delays, allow installation costs to soar, and weigh heavily on your peace of mind. Many Enercon customers are quite proactive in working with our engineers to ensure the…

Read MoreClearing the air on the gap between ceramic coated ground rolls and their bare roll predecessors.

Years ago, corona treating technology was pretty simple and straightforward. There were two types of corona treating systems to choose from: Covered Roll systems and Bare Roll systems. Since that time ceramic coated ground rolls have revolutionized bare roll systems. These systems have become popular because they provide more power than their predecessors and also eliminate common problems associated with…

Read MoreFlexo Ink Adhesion & Surface Treatment Insights

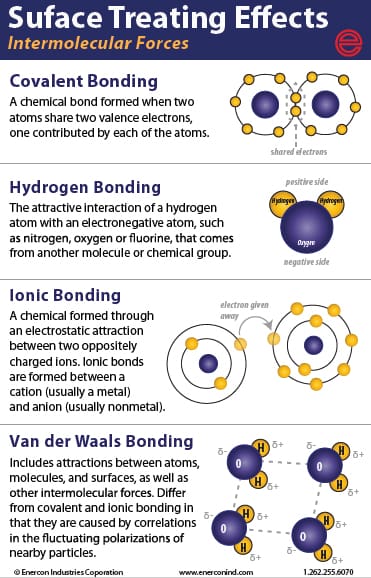

So, do you think you know everything there is to know about surface treatment? Well, let us pose a few questions to test your IQ on this subject: Before you search for the answers within this article, let’s explore some other surface treatment tenets you might find revealing. First, when we talk about surface treatment,…

Read MoreMore science and less art make printing operations more profitable.

Steve Utschig is a man of science. Not that he has anything against art. In fact, he helps people print works of art, but he knows a scientific approach to printing leads to repeatability. And repeatability breeds profitability. His approach is well grounded and based on his 22 years of converting industry experience. As a…

Read More