Corona Treater Start-Up Assistance

Enercon’s start-up assistance programs are used by leading converting and extruding operations to verify their corona treater installations follow Enercon’s best practice recommendations. During start-up assistance a factory trained engineer from Enercon will work with your team and review all aspects your corona treater installation including; safety, utilities, mechanical & electrical integration, materials used, &…

Read MoreImprove Print Quality & Productivity by Controlling Substrate Surface Energy

Poor ink adhesion affects print quality, creates downtime, and leads to lost customers. In many cases, the cause is rooted in complications from the substrate surface. The good news is that surface variables can be eliminated with the proper use of a corona treater. A common misunderstanding is that pretreated films eliminate the need for…

Read MoreCorona Treatment For Extruded Film (Cast & Blown Film)

Most cast and blown film extruding applications are best served with a covered roll surface treater. Enercon offers two types of covered roll systems for extruding applications. Our original covered roll system is designed to meet the needs of the high-performance lines and our new blown film station capably handles the requirements of lower speed…

Read MorePurged surface treater safely allows solvent printers to run faster and reduce costs.

Solvent-based printers are recognizing the benefits of surface treating and Enercon has specifically designed a surface treater to meet their solvent printing needs. The system puts quality control in the printers’ hands by ensuring optimal substrate surface energy. Materials with higher surface energy may require a secondary (or “bump”) corona treatment of the substrate to…

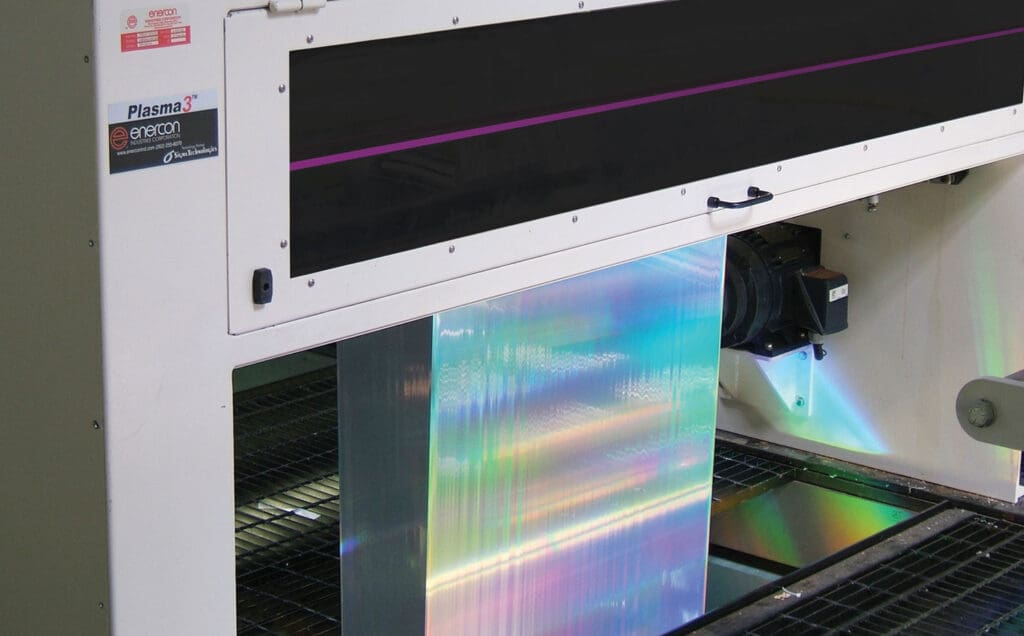

Read MoreMetallized Film Adhesion: Processing & Converting with Surface Treatment

Metallized film presents adhesion challenges to both film suppliers and converters. Today, new developments in surface treatment are creating competitive advantages by extending surface energy stability on metallized film. What metallized film converters should know Both the metallized film supplier and converter are at the mercy of the physics involved with dyne levels. Dyne level…

Read MoreImprove Lamination Adhesion with Surface Treating

For many industrial applications, the use of a single ply of a material does not provide all of the critical properties required for the optimal performance of a product. In these cases, a composite of two or more layers of material can provide this required performance. A common method of creating such a composite is…

Read MoreImprove Ink Printing Adhesion with Surface Treating

The task of optimizing printing adhesion can be difficult, primarily because of the many process variables which require control. The most critical of these parameters are 1) ink chemistry, 2) substrate quality, 3) surface treatment, and 4) ink transfer method. There are six major printing/decorating processes, each distinguished by the method in which ink and…

Read MoreCompak 2000 flip top power supply provides fast and easy diagnostic troubleshooting.

The most recent improvement to Enercon’s line of power supplies is the new Compak™ 2000 Flip-Top style power supply. At first glance you’ll notice a change in the size of the cabinet. You might also notice a minor change in the diagnostic display symbols and the description of the diagnostics offered. The diagnostics are intended to provide…

Read MoreExtruding Applications

Most cast and blown film extruding applications are best served with a covered roll surface treater. Enercon offers two types of covered roll systems for extruding applications. Our original covered roll system is designed to meet the needs of the high-performance lines and our new blown film station capably handles the requirements of lower speed…

Read MoreOptimizing Blown Film Line Layouts For Improved Surface Treating Performance

In today’s race to produce film faster, thinner and with lower tension, reliable surface treatment is critical for success. There are a number of different philosophies employed when setting up a blown film line. Variables such as budget, available space, and specific application needs vary, but there are certain undeniable principles that can be used…

Read More