Which Surface Treatment Technology is Best for Your Application?

Corona? Plasma? Flame? Which one is truly the best technology? Well, that depends on what you are trying to accomplish. Each of these technologies offers unique benefits, as well as practical limitations. And, they can all help you improve adhesion, but your application objectives, budget, and operating parameters will help determine which technology is best…

Read MoreCorona Treating Essentials for All Types of Blown Film Lines

Whether you produce complex multilayer MDO structures for flexible packaging or operate traditional blown film lines to produce material for bags, ensuring your operators understand the corona treating process is critical for your success. Watch this webinar as Enercon Experts share insights on the essentials needed for successful corona treating and the latest developments in technologies…

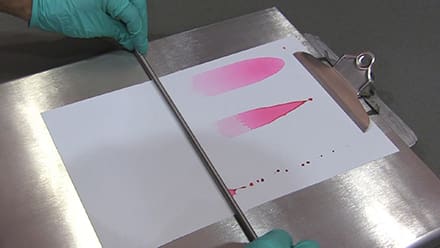

Read MoreTruth or Dyne? How to Properly Conduct Dyne Tests & What Your Results Really Mean

Corona treaters are used to increase a film’s surface energy to enable wettability & promote the adhesion of inks, coatings and adhesives. This change in surface energy is most commonly measured in dynes. And that’s where problems for extruders and converters begin. Poorly executed dyne tests produce unreliable results and assumptions about dyne levels lead…

Read MoreCorona Treating Essentials for Printing Flexible Packaging & Labels

Watch this webinar and you’ll gain a clear understanding of how to use corona treatment to improve ink adhesion when printing flexible packaging, labels and more. Our expert panel reveals industry best practices: Regardless of the brand of corona treater you currently use and whether you print on narrow, mid or wide web films, this webinar…

Read MoreNext Generation Corona Treaters: How Smart New Features Will Make Your Operation More Profitable

Start/Stop. Power Up/Down. Who could ask for more? Well, you should; and now Enercon is making it possible. To compete at a high level, you need the right technology to support your operation. We’re talking about innovative systems that do the thinking for you. Enercon’s design engineering team has developed leading edge technology to take…

Read MoreTips for Optimizing Liquid Coating & Laminating Lines for Your Application

The first step in building a world class liquid coating line is properly defining the application. Product development in flexible packaging, labels, tapes, window film and paint protection are presenting challenges to both converters and machinery manufacturers. Whether you are considering a new coating line or considering new applications with your existing line, this webinar…

Read MoreCorona Treater Installation Best Practices: Prevent Downtime

When properly installed, maintained and operated, corona treaters are one of the most reliable pieces of equipment on your line. But did you know that over half of corona treater downtime is associated with mistakes made during the installation of the original equipment? This means that 50% of corona treater downtime is easily preventable. Symptoms…

Read MoreBlame the Corona Treater: The Truth About Watt Density, Dyne Level & Adhesion

When inks, coatings, adhesives and laminates don’t bond with substrates, converters are quick to blame the corona treater. And why shouldn’t they? Corona treaters are responsible for adhesion, right? Well, not exactly. In this insightful webinar, industry veterans Tom Gilbertson and Todd Krupa dive deep into the relationships between watt density, dyne levels and adhesion.…

Read MoreComexi Printing Technologies

Enercon Interviewed Carles Rodríguez i Nieto, Vice President of Comexi North America Enercon’s corona treater power supplies and treater stations are integrated with leading OEM printing press manufacturers to ensure reliable performance. Read on for the latest technical advancements from the Comexi team. What options do you have for remote support of your customers? This…

Read MorePrevent Heat & Humidity from Creating Corona Treater Downtime

As the weather warms up outside, increased heat and humidity in your facility can affect your corona treater operation. If your corona treater has not been properly maintained the combination of dirt, debris, and high voltage, along with increased temperatures and humidity, will wreak havoc on your productivity. The good news is that downtime and…

Read More