Prevent Backside Treatment

The bad news is that backside treatment mitigates the effects of surface treating. In some cases, it results in under treatment of substrates. It can also raise the energy of the backside surface creating processing problems. In bag making and seal applications, backside treatment can alter the substrate’s co-efficient of friction. This will ultimately cause…

Read MoreExtrusion Coating Bonding Success Improved with Surface Treating

Chances are you or someone you know has a secret family recipe for a great barbecue sauce, or chili or killer cheesecake. In each case, there’s probably a unique combination of ingredients that makes all the difference in the world. As a professional in the extrusion industry, you can probably relate the family recipe analogy…

Read MoreOptions for Surface Treating Extruded Film

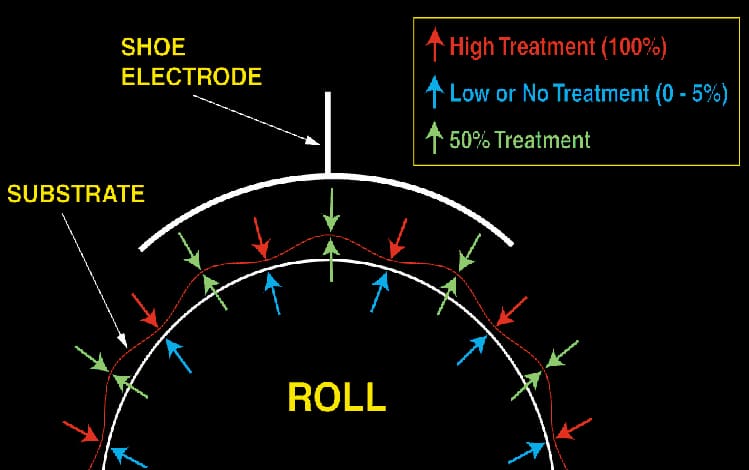

Traditionally, film extrusion lines utilize a metal electrode and covered roll configuration. However, there are exceptions. Some companies choose a Bare Roll system to eliminate any roll covering concerns. While others have selected a new Plasma3™ atmospheric plasma system for their extruded film applications. Fixed or segmented applications? For simple applications that do not require lane treating, a…

Read MoreCorona Treating Installation Planning Saves Money and Time

An accurate cost assessment of any piece of converting equipment ought to include a review of installation cost. Proper planning will eliminate avoidable variables that create project delays, allow installation costs to soar, and weigh heavily on your peace of mind. Many Enercon customers are quite proactive in working with our engineers to ensure the…

Read MoreSurface Treating For Solar Cell Converting

The art of optimizing continuous processing techniques for flexible materials has long been practiced in the converting industry. The accrued benefits range from consistent product quality and waste minimization to lower conversion cost per square meter. And a key component in the optimization of many web converting processes is consistent and uniform surface modification by…

Read MoreEnercon Tech & Support Helps Converters & Film Extruders Grow at Record Pace

Release date: 12/8/2021 Business is booming for Enercon’s customers in the converting and film extruding businesses. And, at no other time in history has the relationship between equipment users and suppliers been more important. The impact of the global pandemic magnified the importance of reliability and support. Customers who have selected Enercon for their surface…

Read MoreMalaysian Extruders & Converters Rely on Enercon Representative PS Equipments for Technology & Support

Release date: 9/13/2021 PSEQ’s General Manager Joseph Looi says that converters in Malaysia are moving towards non-solvent inks and adhesives. There are many benefits of water-based formulations including environmental, safety and lower costs. However, what many converters are quickly learning is that corona treatment is required to achieve successful adhesion with water based inks, coatings,…

Read MorePlasma4™ Surface Treating Technology Wins Innovation Award

MENOMONEE FALLS, WI – Enercon Industries was presented with the C2 Innovation Award at ICE Europe in recognition of the development of Plasma4™ surface treatment technology. This revolutionary pretreatment technology is acknowledged for breaking ground in productivity, ecology and economy. Plasma4™ was chosen by an international jury charged with identifying most innovative products, processes and technologies…

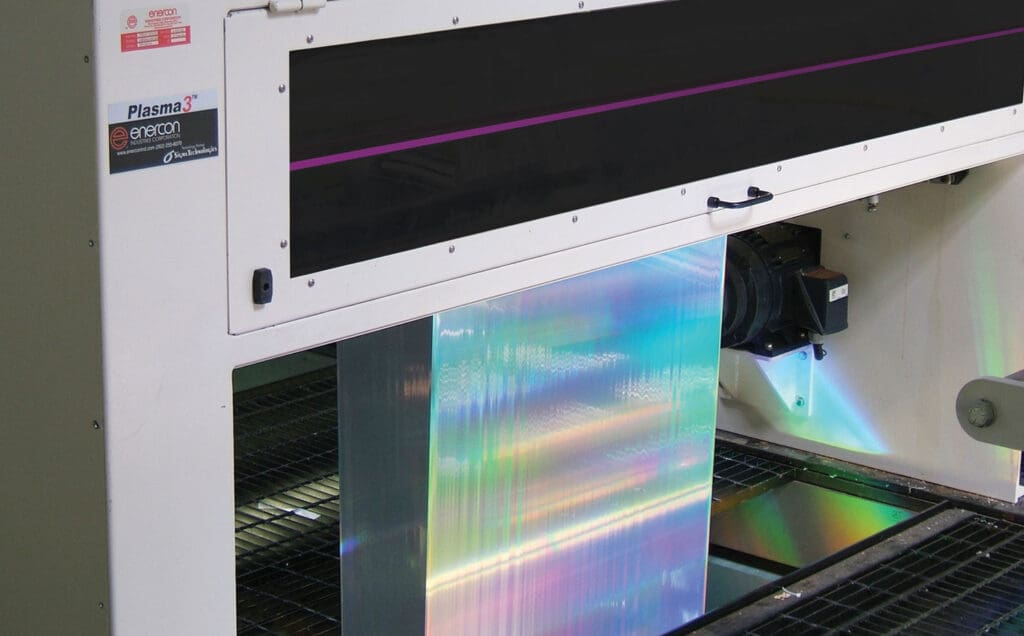

Read MoreEnercon’s Plasma3 Improves Printing on Tyvek

MENOMONEE FALLS, WI – Recent customer trials confirm Enercon’s Plasma3™ atmospheric plasma surface treater improves printing on a wide variety of materials used in the medical industry including Tyvek®. The unique technology is able to raise surface energy to improve ink adhesion while leaving physical, mechanical and barrier surface properties intact. Atmospheric plasma treatment provides…

Read More